Managing a complex inventory is no simple task. Without practical inventory management tools, poor inventory management can result in stockouts, cash flow issues, customer dissatisfaction, and a slew of operational inefficiencies.

This blog post will discuss the top 20 inventory management challenges businesses face in 2026 and provide a corresponding solution to each issue. Let’s dive in!

Key Takeaways:

- Inventory management is the process of overseeing and controlling stock levels, ordering, storing, and selling inventory to optimize operations and reduce costs.

- Common challenges include stockouts, overstocking, inaccurate demand forecasting, and operational inefficiencies.

- A retail POS solution can streamline inventory management, improve analytics, and boost profitability for businesses of all sizes.

What is Inventory Management?

Inventory management focuses on monitoring stock levels, planning inventory, and ensuring product availability for customers.

While contemporary retail inventory management utilizes reporting and analytics tools, traditional instruments like inventory spreadsheets remain significant.

The Most Common Inventory Management Challenges (and Solutions)

When managing inventory, challenges are sure to arise. Keep reading to understand the 20 most common inventory management hiccups (and how a system like KORONA POS and some best practices can resolve these issues in no time).

Problem 1: Stockouts

Stockouts happen when businesses underestimate demand or fail to reorder inventory on time. They can result from poor demand forecasting, inefficient reorder systems, or a lack of real-time inventory tracking.

Frequent stockouts cause lost sales and damage customer trust and loyalty, as buyers often turn to competitors. Seasonal spikes or unexpected surges in demand exacerbate this problem, demonstrating why proactive inventory monitoring is so essential.

Solution: Automated Inventory Alerts

KORONA POS’s automated inventory management features send real-time alerts for low stock levels. Users can even set up automatic reordering when an item reaches a critical threshold. Not to mention the vast array of demand forecasting and inventory tracking tools that can also help prevent stockouts.

Problem 2: Overstocking

Overstocking occurs when businesses order more inventory than necessary, often due to inaccurate sales forecasts or bulk purchase discounts. Excess stock ties up capital, increases storage costs, and risks spoilage or obsolescence, particularly in industries with perishable goods or tech products.

Overstocking can also lead to markdowns, eroding profit margins, and inefficient use of storage space, which might otherwise be used for faster-moving items.

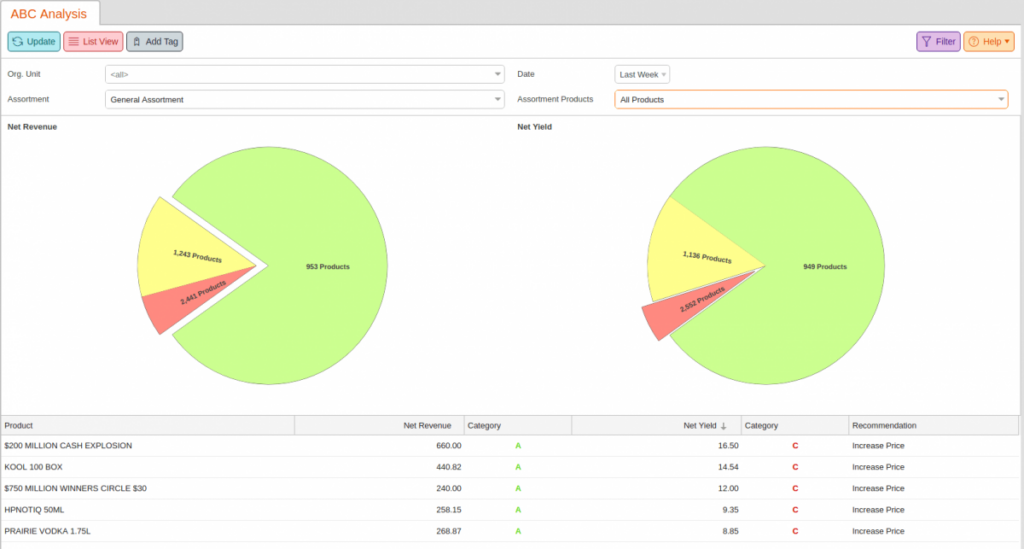

ABC analysis helps businesses categorize their best- and worst-performing inventory over time. “A” items are goods with the highest annual consumption value; “B” items are right in the middle; and “C” items are the slowest-moving items in an inventory.

You can run an ABC analysis in two different ways: manually or through inventory management software. KORONA POS features an ABC Analysis tool to run the numbers for you.

Problem 3: Inaccurate Demand Forecasting

Demand forecasting errors arise from relying on outdated inventory methods, lack of access to historical data, or ignoring critical factors like market trends and seasonality. Misjudging demand leads to stock imbalances—either surpluses or shortages.

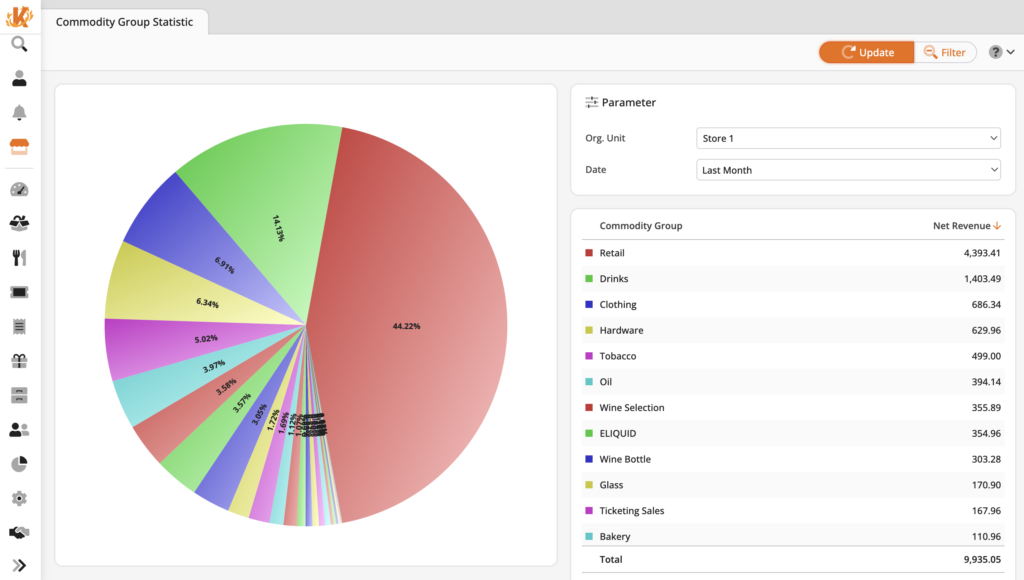

Solution: POS Reporting and Analytics

Accurate inventory forecasting requires data-driven insights and robust analytical tools to factor in variables like promotions, local events, and customer behavior. KORONA POS’s robust reporting and analytics tools can do that and more, so you know exactly what to expect as seasons change.

Problem 4: Inefficient Multichannel Tracking

Businesses with multiple sales channels often struggle to maintain consistent stock levels across platforms. This is especially problematic for eCommerce businesses managing inventory across marketplaces like Amazon, Shopify, and physical stores.

Manual updates across platforms can lead to overselling or stockouts, thereby frustrating customers and complicating returns. Integrated multichannel management tools are essential for maintaining accurate inventory across all sales points

Solution: Multichannel Inventory Management

Cloud-based multichannel inventory management tools synchronize stock data across platforms, making inventory information for any store accessible from anywhere. The right multichannel inventory management software should be tailored to your industry’s specific needs, integrate with your existing systems, and offer scalability for future growth.

KORONA POS lets users manage inventory for multiple channels within the software through its Organizational Units feature, saving users time and money that would be better spent elsewhere.

Problem 5: Obsolete Inventory

Obsolete inventory results from misjudged purchasing decisions, product seasonality, or changes in customer preferences. This type of inventory sits unsold for extended periods, losing their value and occupying precious storage space.

For businesses that sell perishable goods, obsolete inventory could mean complete loss. However, regular inventory reviews and smarter procurement strategies, such as demand-driven restocking, can mitigate this issue.

Solution: Inventory Turnover Analysis

Inventory turnover measures the number of times a business sells through its assets in a set period. It’s a measure of how efficiently a company manages and uses its inventory – the higher the inventory turnover rate, the better!

Specific inventory turnover analysis tools, like the inventory turnover ratio, help businesses track inventory turnover data and make smarter inventory decisions. The Key Performance Report in KORONA Studio lists your inventory turnover rate, which you can check consistently and in real-time.

Inventory management headache?

KORONA POS makes stock control easy. Automate tasks and get a clear picture of your entire inventory.

Problem 6: Lack of Real-Time Updates

Without real-time inventory updates, businesses are destined for inaccuracies and inefficiencies. Manual systems delay visibility into stock levels, making it difficult to promptly meet demand or identify shortages.

This lack of transparency hampers quick decision-making, causing overstocking, stockouts, or missed sales opportunities—no business wants that.

Solution: Automated System with Update Features

Real-time POS updates, a central feature of KORONA POS, give users live, updated inventory data and analytics with each new purchase. The software breaks down your sales and inventory metrics in digestible ways so you know how you’re doing and what changes need to be made.

Problem 7: Human Errors in Stock Management

Nobody is perfect. Manual inventory tracking is prone to human errors, such as incorrect data entry, duplicate records, or misplacement of stock. These errors disrupt operations, cause discrepancies in stock counts, and erode customer trust when items marked “in stock” aren’t available.

Automating repetitive tasks reduces the likelihood of making a mistake. (It saves you lots of time, too).

Solution: Perpetual Inventory Systems

Automated inventory systems, also known as perpetual inventory systems, reduce reliance on physical counts and other manual processes. Barcodes and RFID are some of the tools of the trade—they save you loads of time so you can dedicate yourself to more critical tasks.

Our post on periodic versus perpetual inventory systems highlights just how revolutionary automated systems are for businesses managing complex inventories.

Problem 8: Inefficient Warehouse Organization

Disorganized warehouses slow down order fulfillment, increase labor costs, and lead to misplaced inventory. Common reasons include poor layout design, lack of categorization, or insufficient storage solutions.

Efficient warehouse organization saves time, reduces operational costs, and ensures that inventory is easy to locate, track, and restock.

Solution: RFID Asset Tracking Systems

A radio frequency identification (RFID) system uses tiny computer chips and waves to track real-time assets moving through a warehouse. Notably, RFID eliminates the need for manual counts or running around a warehouse searching for an item. You’ll instantly know what’s on hand and where it is.

KORONA POS has joined forces with Radio Enabled Solutions (RES) to integrate RFID capabilities into your POS software, ensuring greater efficiency and enhanced control in your warehouse operations.

Problem 9: Ineffective Reporting

Inadequate inventory reporting leaves decision-makers without the insights to optimize stock levels, reorder points, and sales strategies. When reporting tools are too generic or difficult to interpret, businesses miss opportunities to reduce costs or boost revenue.

Tailored reporting systems provide actionable insights that help managers identify trends and make data-informed decisions.

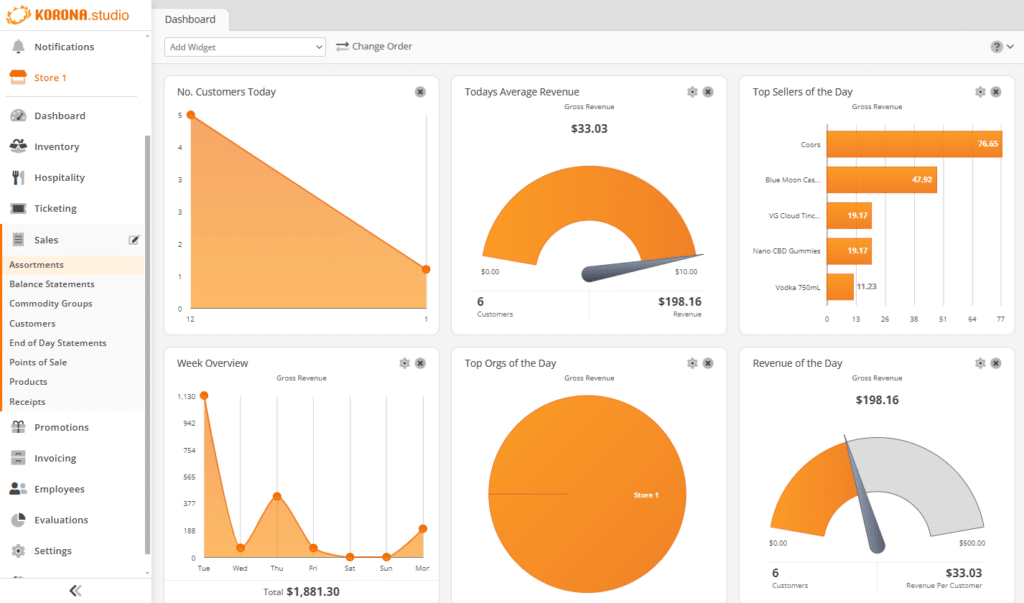

Solution: Retail KPI Dashboards

A Retail KPI (Key Performance Indicator) Dashboard is a visual tool that provides a quick, comprehensive overview of a retail business’s most important performance metrics. It includes easy-to-understand graphs, charts, and tables, covering a wide range of sales, inventory, customer behavior, and employee performance data.

KORONA POS offers a highly customizable KPI dashboard. This dashboard allows you to visually analyze metrics related to your current orders, customers, products, sales, and more.

Problem 10: High Shrinkage Rates

Shrinkage–inventory loss due to theft, damage, or administrative errors, is a significant issue for retailers managing inventory. Poor security measures, insufficient training, or lack of inventory tracking exacerbates the problem.

Shrinkage impacts profitability directly, making implementing robust tracking systems, secure storage, and employee accountability measures vital.

Solution: POS Security Features

KORONA POS offers a range of customizable POS security features dedicated to retail loss prevention. Managers can leverage authorization measures for creating discounts, using accurate balance verification tools, viewing cashier actions, and much more to save the business thousands on shrinkage and theft.

Learn how to manage your inventory effectively with this free eGuide.

Problem 11: Seasonal Demand Fluctuations

Seasonal variations in demand, such as holiday shopping or back-to-school seasons, challenge businesses to maintain optimal inventory levels. Overestimating demand can lead to excess inventory while underestimating it can result in stockouts.

Advanced analytics and historical data help businesses prepare for these fluctuations, ensuring balanced and relevant stock levels year-round.

Solution: Historical Data Analysis

Looking back at how your inventory performed throughout previous years’ seasons can help you understand inventory trends and better prepare for the future. KORONA POS offers a Stock History Report, among other analytical tools, to review stock trends for as long as you have collected data.

Problem 12: Complex Pricing Structures

Frequent price changes due to market trends, competitor actions, or promotional campaigns complicate inventory valuation. Incorrect pricing not only affects sales but also disrupts inventory accounting.

Additionally, these fluctuations can lead to inconsistencies in financial reporting and hinder business decision-making. Automated pricing systems ensure consistency and make it easier to manage price adjustments across multiple products and categories.

Solution: Retail Pricing Optimization Software

Retail pricing optimization software is a super-powered pricing assistant for businesses. It analyzes large amounts of data, including competitor prices, customer behavior, and market trends, to suggest and adjust pricing strategies across your inventory.

KORONA POS integrates with pricing optimization software, allowing you to streamline and automate your pricing right at the point of sale.

Problem 13: Inefficient Order Management

Order management inefficiencies often result from poor supplier communication, a lack of automation, or reliance on manual processes. Delays in reordering, lost purchase orders, or missed delivery deadlines directly disrupt inventory flow.

Integrated order management systems improve supplier coordination and streamline procurement processes, removing your ordering process’s messiness.

Solution: Order Management Tools

KORONA POS offers multiple features for order management, including Instant Stock Orders, the Instant Order Portal, and the option to apply suppliers to products. These tools allow users to set up automated ordering systems and track deposits, e-mails, and delivery times associated with suppliers.

Problem 14: No Scalability

Many businesses outgrow their inventory management database as they expand. Systems that can’t handle increased SKUs, sales volume, or warehouse locations become bottlenecks, leading to inefficiencies and missed opportunities. Without scalability, businesses may struggle to meet customer demand and lose market share to more agile competitors.

Solution: Scalable POS Systems

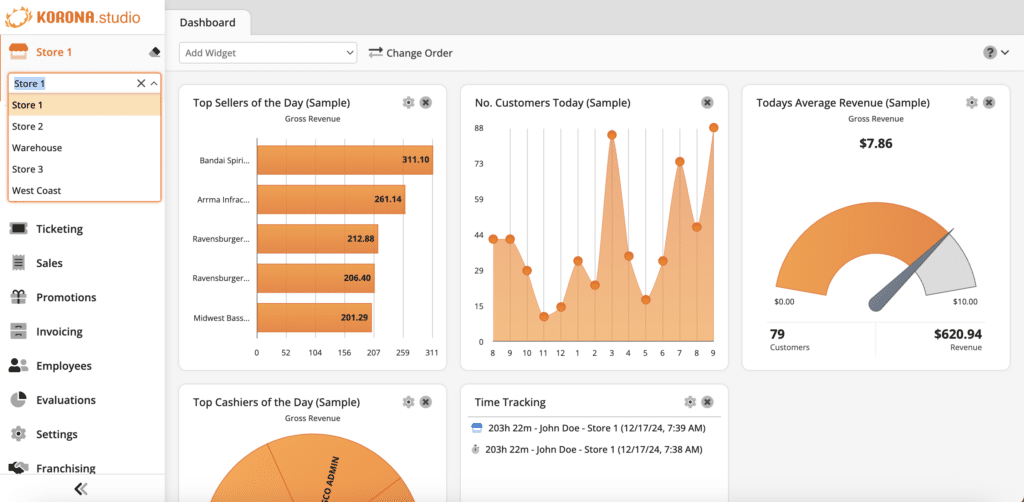

Scalable solutions allow businesses to grow without disruptions, meaning seamless operations as they expand. KORONA POS stands out as a top multistore POS system due to its robust multi-location inventory management capabilities, seamless tracking and control across various store locations, and ability to manage employees and customers across locations and from anywhere.

Problem 15: Poor Employee Training

Employees who don’t understand inventory systems—or how important they are to manage well—can misuse tools, make errors, or fail to follow procedures. Poor training leads to inefficiencies, inaccuracies, and higher shrinkage rates. Ultimately, inadequate training can result in significant financial losses and damage a company’s reputation due to mismanaged stock levels.

Solution: Staff Training Programs

To address the issue of poor employee training, businesses should develop comprehensive training programs tailored to their inventory systems and processes. These programs should include hands-on practice, clear documentation, and periodic refresher courses to ensure employees stay current on all things inventory and POS.

Using KORONA POS’s inventory manual or scheduling a training session are two ways to tackle this issue with direct support from your POS system.

Discover Advanced Analytics and Custom Reports

Speak with a product specialist and learn how KORONA POS can power your business needs.

Problem 16: Low Stock Visibility

Limited visibility into current stock levels complicates decision-making, leading to overordering, stockouts, or missed sales opportunities. This is especially relevant for businesses that use physical counts as an inventory management method.

Without visibility, businesses can’t accurately plan restocks or identify inventory bottlenecks. Tools like RFID and real-time dashboards enhance stock visibility and transparency.

Solution: Invest in Stock Visibility Tools

Low stock visibility can be resolved by investing in tools like real-time dashboards, RFID tags, or barcode scanners. These technologies provide instant updates on inventory levels and movement, ensuring accurate tracking across locations.

Cloud-based inventory systems further enhance visibility by offering accessible, centralized data.

Problem 17: Lack of Customization

Generic inventory systems fail to meet industry-specific needs, leading to inefficiencies across the organization. For example, a bakery requires tools for managing perishable items, while a liquor store might need unique tracking for age-restricted products.

Solution: Industry-Customizable Software

Customizable inventory solutions ensure that businesses can tailor systems to their unique requirements. KORONA POS offers hundreds of tailored solutions and integrations for multiple highly-specialized industries, like cannabis, smoke shops, liquor stores, and wineries.

Problem 18: Limited Data Access

When inventory data is only accessible in certain locations or at specific times, it slows decision-making and complicates operations. Cloud-based systems eliminate these barriers, allowing 24/7 access to inventory data from any device. This is especially important for businesses with remote teams or multiple locations.

Solution: Cloud-Based Systems

Limited data access can be eliminated by transitioning to cloud-based inventory systems, like KORONA POS. These platforms offer 24/7 access from any device, allowing teams to check stock levels, place orders, or generate reports remotely.

Cloud-based systems also provide secure, real-time data synchronization across locations, ensuring operational consistency and enabling faster, data-driven decisions.

Problem 19: Fragmented Operations

Using separate tools for inventory, sales, and reporting creates silos that hinder operational efficiency. Meanwhile, data inconsistencies and lack of integration lead to errors and wasted time. Unified retail management systems integrate these functions, providing a seamless workflow and reducing redundancies.

Solution: Unified Retail Management Systems

Fragmented operations can be resolved by integrating inventory management with other business functions, such as point of sale, purchasing, and reporting. Unified retail operations software like KORONA POS eliminates silos by providing a single platform for managing all workflows.

Problem 20: Lack of Transport Capacity

Transportation capacity constraints can disrupt inventory flow, causing replenishment and order fulfillment delays. This issue often stems from limited carrier availability, rising fuel costs, or logistical inefficiencies, particularly during peak seasons.

Supply chain disruptions, such as natural disasters or labor shortages, exacerbate the problem, making it difficult for businesses to maintain consistent inventory levels and meet customer expectations.

Solution: Supplier Management Tools

To address transportation capacity issues, businesses should optimize logistics by collaborating with reliable carriers, using route optimization tools, and diversifying transportation options. Building contingency plans, such as securing backup carriers or using third-party logistics providers, ensures resilience during disruptions.

Additionally, investing in inventory forecasting using robust solutions like KORONA POS can help businesses align stock movements with transportation availability, minimizing delays and maintaining smooth operations.

Speak with a product specialist and learn what KORONA POS can do for your business.

Overcome Your Inventory Management Challenges With KORONA POS

Effective inventory management is the backbone of a successful business. KORONA POS offers a comprehensive solution that tackles these issues head-on, with real-time tracking, advanced analytics, and automation.

Don’t let inventory problems hold your business back—explore how KORONA POS can revolutionize your inventory management today!

Frequently Asked Questions (FAQ)

How do you fix poor inventory management?

Fixing poor inventory management involves implementing robust systems that provide real-time tracking, accurate forecasting, and automated processes. Training employees, integrating inventory with other business operations, and leveraging data analytics can also help streamline operations and reduce errors.

What are the outcomes of poor inventory management?

Poor inventory management can lead to stockouts, overstocking, decreased cash flow, dissatisfied customers, and operational inefficiencies. Over time, these issues can harm a business’s reputation and profitability.

How can we improve the effectiveness of inventory management?

To improve inventory management, businesses should use advanced tools, such as POS systems with inventory tracking, predictive analytics, and automated reordering. Regular audits, staff training, and clear supplier communication will enhance inventory efficiency and accuracy.