Key Takeaways

- Slow-moving inventory refers to products that sell very slowly or sit in storage longer than expected.

- Use data like sales reports, inventory turnover, and days in inventory to spot these items early.

- Regular reviews of stock levels and product performance help prevent excess buildup.

- Promotions or bundling can help move stagnant products and free up cash flow.

- Better forecasting and smarter purchasing decisions reduce future slow-moving stock.

Overstocked inventory is unavoidable for almost all retailers, from mom-and-pop shops to big-box stores. It’s nearly impossible to predict fads and trends, and the economy can be volatile. While sales reporting from past years can certainly be helpful, it will never be a perfect indicator of the future.

Whether you’ve purchased too much product or perhaps an item simply isn’t selling, there are ways to mitigate the problem. Explore this guide on clearing slow-moving inventory from your store while boosting your cash flow.

What Is Slow-Moving Inventory?

Slow-moving inventory refers to products that retail companies store for a period of time that they deem to be taking too long to sell. Different businesses have different time frames in which they identify goods as slow-moving. Obviously, for some businesses, items become obsolete faster than others.

Companies decide what makes sense for them depending on what they’re selling. For example, if you sell bathing suits and the summer ends, those bathing suits are going to sit around all winter. Or for instance, if you plan on opening a convenience store you will have products like milk and eggs with expiration dates that will make them worthless past a certain date.

On the other hand, if you own a hardware store and sell nails and wrenches, you’re likely not going to see those items become obsolete so quickly. As such, your time frame will differ in determining which items are slow-moving. Most businesses use a 90, 120, or 180-day window to analyze the performance of an item. In addition, point of sale technology can provide businesses with real-time reports to show the rate of sale for particular items without having to do physical inventory counts.

Why Slow-Moving Inventory Hurts Businesses? (A conclur

Unfortunately, having overstocked inventory can be crippling for a retail store. It ties up capital, preventing retailers from bringing in new products that will sell better. In industries that rotate seasonally, this can mean that an entire product line is delayed from being on the shelf.

Overstocked products also take up valuable shelf space. Most retail stores are rented, so every square foot must be used to sell. Any items sitting on the shelf for months are just wasting space, and costing you money by preventing a product that would actually sell from being there.

Many retail stores face this issue most dramatically after the winter holiday season. It’s important to prepare for it now. No amount of market research or sales predictions can completely prevent it. Let’s explore a few ways to combat this problem.

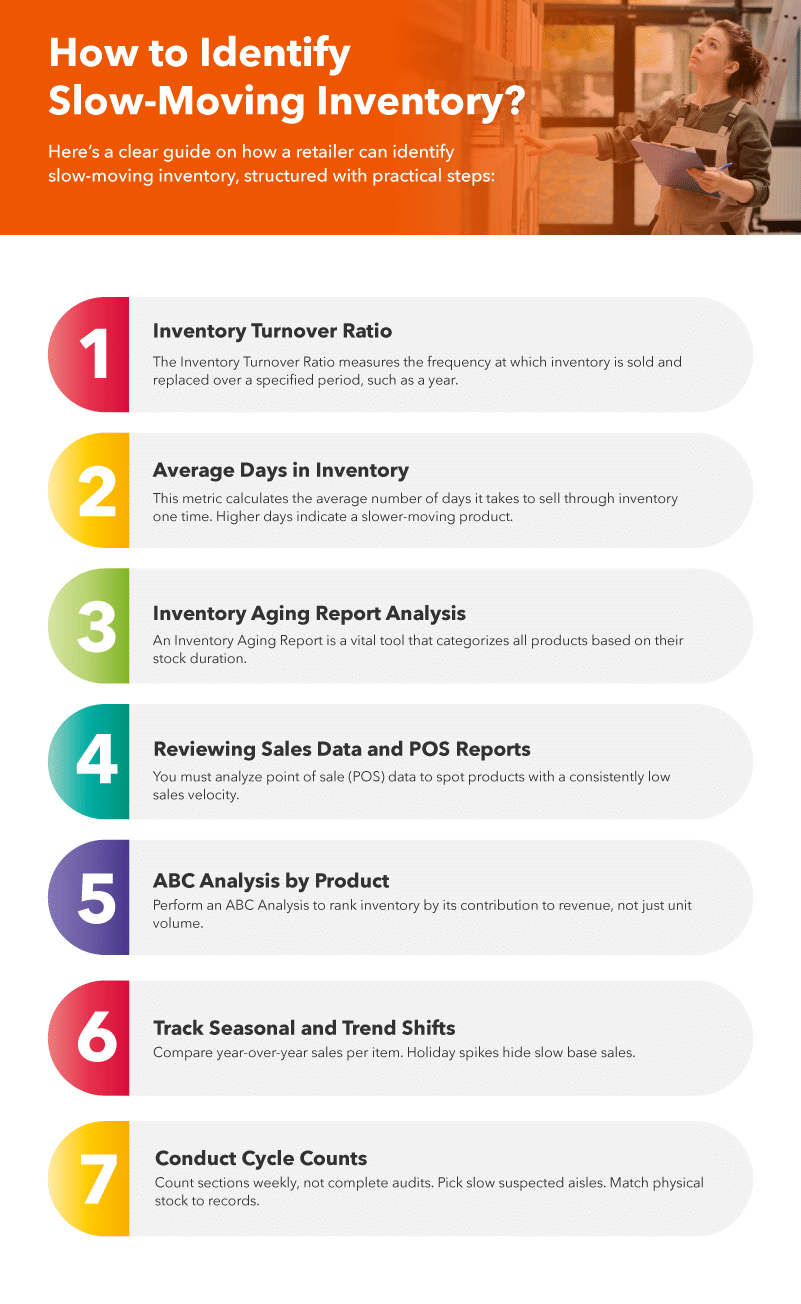

How to Identify Slow-Moving Inventory?

Here’s a clear guide on how a retailer can identify slow-moving inventory, structured with practical steps:

Inventory Turnover Ratio

The Inventory Turnover Ratio measures the frequency at which inventory is sold and replaced over a specified period, such as a year. A low ratio indicates that products are sitting on the shelf for too long. Formula: Cost of Goods Sold (COGS) divided by average inventory value.

Example: COGS of $100,000 yearly. Average inventory $20,000. Turnover = 100,000 / 20,000 = 5. Means stock sells out 5 times a year. Below 4 signals slow movers.

Average Days in Inventory

This metric calculates the average number of days it takes to sell through inventory one time. Higher days indicate a slower-moving product. Formula: 365 divided by turnover ratio.

Following the previous example, $365 / 4$ equals $91.25$ days. This shows it takes over three months to sell the average stock, which is slow for many retail items.

Inventory Aging Report Analysis

An Inventory Aging Report is a vital tool that categorizes all products based on their stock duration. It groups inventory into time buckets, like 0-30 days, 31-60 days, and $90+$ days. A large percentage of stock falling into the older buckets (e.g., $90+$ days) immediately flags them as slow-moving.

Reviewing Sales Data and POS Reports

You must analyze point of sale (POS) data to spot products with a consistently low sales velocity. Look for items with zero or minimal sales for an extended period, especially compared to similar products in the same category. These reports instantly isolate the specific Stock Keeping Units (SKUs) that require immediate action, such as a price markdown.

ABC Analysis by Product

Perform an ABC Analysis to rank inventory by its contribution to revenue, not just unit volume. “C-Grade” products are those that generate the lowest revenue, despite possibly having a large quantity in stock. These C-grade items are primary candidates for classification as slow-moving and requiring liquidation strategies.

Track Seasonal and Trend Shifts

Compare year-over-year sales per item. Holiday spikes hide slow base sales. Use graphs in reports to see dips. Forecast with past data. If an item lags post-season, tag it. Adjust buys down. Tools like Google Sheets plot trends easy. Catch fads early to avoid bulk buys on flops.

Conduct Cycle Counts

Count sections weekly, not complete audits. Pick slow suspected aisles. Match physical stock to records. Discrepancies show hidden slow movers. Train staff quickly. Log variances in app. Ties to real sales gaps. Fixes overcount errors. Builds a habit of keeping a sharp eye on shelves.

Strategies to Manage Slow-Moving Inventory

Dealing with slow-moving inventory is crucial for business health. Here are several effective strategies to manage it:

Sales and Pricing Adjustments

- Bundle Items: Group slow-moving products with faster-selling items. Sell them as a package deal at a slightly reduced combined price.

- Introduce Markdowns/Clearance: Use significant, final price cuts. Emphasize that the stock must go.

- Use Tiered Pricing: Offer deeper discounts for buying in larger quantities. Encourage bulk purchase.

Marketing and Sales Focus

- Reposition the Product: Change how the item is presented. Target a different customer segment or a new use.

- Incentivize Sales Staff: Offer bonuses or higher commissions for selling specific slow-moving goods. Motivate your team to prioritize those items.

- Limited-Time Offers: Create a sense of urgency with a special, short-term promotion. Encourage immediate purchasing decisions.

- Run Targeted Promotions: Focus marketing efforts specifically on the slow-moving items. Highlight their value or unique features.

Product and Operations Strategies

- Donation or Disposal: Donate items to charity for a potential tax write-off. As a last resort, dispose of the stock to free up warehouse space.

- Kitting and Assembly: Use slow-moving components in the production of new, popular items. Integrate them into fresh products.

- Staff Use or Giveaways: Give items to employees or use them as promotional gifts. Generate goodwill instead of letting them sit.

- Return to Supplier: If possible, negotiate a return of unsold stock to the vendor. Recover some capital.

Prevention and Review

- Optimize Ordering: Implement a more streamlined and disciplined purchasing process. Only buy what you truly expect to sell within a reasonable period.

- Regular Inventory Review: Consistently check stock levels and sales velocity. Identify potential slow movers early, before the issue worsens.

- Improve Forecasting: Analyze sales data to more accurately predict demand. Prevent over-ordering in the future.

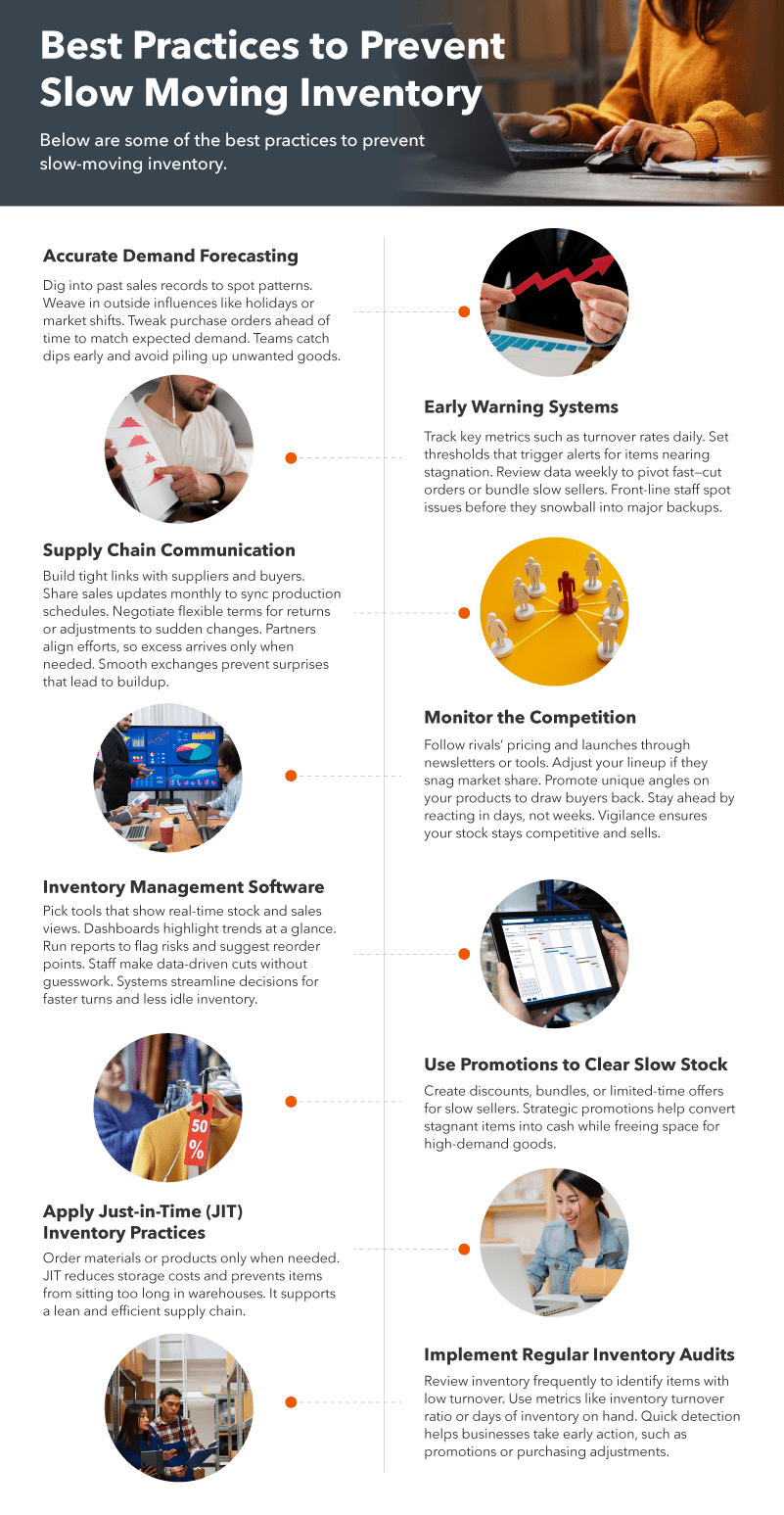

Best Practices to Prevent Slow-Moving Inventory

Below are some of the best practices to prevent slow-moving inventory.

Accurate Demand Forecasting

Dig into past sales records to spot patterns. Weave in outside influences like holidays or market shifts. Tweak purchase orders ahead of time to match expected demand. Teams catch dips early and avoid piling up unwanted goods.

Early Warning Systems

Track key metrics such as turnover rates daily. Set thresholds that trigger alerts for items nearing stagnation. Review data weekly to pivot fast—cut orders or bundle slow sellers. Front-line staff spot issues before they snowball into major backups.

Supply Chain Communication

Build tight links with suppliers and buyers. Share sales updates monthly to sync production schedules. Negotiate flexible terms for returns or adjustments to sudden changes. Partners align efforts, so excess arrives only when needed. Smooth exchanges prevent surprises that lead to buildup.

Monitor the Competition

Follow rivals’ pricing and launches through newsletters or tools. Adjust your lineup if they snag market share. Promote unique angles on your products to draw buyers back. Stay ahead by reacting in days, not weeks. Vigilance ensures your stock stays competitive and sells.

Inventory Management Software

Pick tools that show real-time stock and sales views. Dashboards highlight trends at a glance. Run reports to flag risks and suggest reorder points. Staff make data-driven cuts without guesswork. Systems streamline decisions for faster turns and less idle inventory.

Use Promotions to Clear Slow Stock

Create discounts, bundles, or limited-time offers for slow sellers. Strategic promotions help convert stagnant items into cash while freeing space for high-demand goods.

Apply Just-in-Time (JIT) Inventory Practices

Order materials or products only when needed. JIT reduces storage costs and prevents items from sitting too long in warehouses. It supports a lean and efficient supply chain.

Implement Regular Inventory Audits

Review inventory frequently to identify items with low turnover. Use metrics like inventory turnover ratio or days of inventory on hand. Quick detection helps businesses take early action, such as promotions or purchasing adjustments.

Case Examples of Slow-Moving Inventory Solutions

Slow-moving inventory requires strategic action to prevent capital from being tied up. Here are two effective solutions retailers use:

1. Product Bundling

Retailers pair slow-moving items with popular, fast-selling products and offer the combination at a slight discount. This strategy increases the perceived value of the less desirable stock. For example, a slow-selling phone case might be bundled with a best-selling charging cable. Customers purchase the bundle to get a deal on the popular item, moving the stagnant case off the shelves quickly.

2. Strategic Repositioning and Theming

Instead of only deep discounting, retailers re-merchandise slow-moving items away from a large, unappealing clearance bin. They create new, attractive displays and use theme-based signage to suggest new uses or seasons. A furniture retailer might take an unpopular armchair and place it in a featured “Cozy Reading Nook” display, highlighting its comfort.

Tools That Help Manage Inventory Smarter

Retailers face stock shortages or excess often. Smart tools track items in real time. They predict demand and sync sales channels. Five options stand out for their practical features. Each cuts errors and boosts sales.

KORONA POS

KORONA POS fits specialty retail best. Think liquor stores, smoke shops, pharmacies, and convenience outlets. It also serves quick-service spots like cafes and bakeries. Ticketing venues use it for merch and snacks. Wineries rely on their tracking for bottles and supplies.

The system handles real-time stock updates. Barcode scanning speeds count. Loss prevention flags theft risks. Set reorder levels to avoid shortages. Mobile access lets staff check levels anywhere. Notifications alert on low stock or expirations.

Multi-location dashboards pull data from all stores. Analytics show top sellers and slow movers. Custom reports guide buying decisions. Integrations link to eCommerce sites. Overall, it sharpens operations without complexity.

Lightspeed Retail

Lightspeed Retail suits growing chains and boutiques. It handles apparel, electronics, and home goods stores well.

Real-time tracking shows stock across locations. Barcode scans update counts fast. Automate reorders when levels drop. Supplier management logs purchases and deliveries. Inventory counts run via mobile apps. Reports highlight sales trends and dead stock.

Multi-channel sync keeps online and in-store levels matched. Over 60 integrations connect to accounting and eCommerce. Low-stock alerts prevent surprises.

The dashboard simplifies audits. Cloud setup means no hardware hassles. It scales as stores expand. Small teams pick it for ease.

Cin7

Cin7 targets multi-channel retailers. Fashion brands and gadget sellers thrive with it. E-commerce heavy shops find it ideal.

Cloud platform centralizes stock views. AI forecasts demand from sales data. Sync orders across Amazon, Shopify, and stores. Real-time updates cut overselling. Batch tracking follows items from the supplier to the sale. Demand planning adjusts for seasons. Integrations cover 700+ apps. Reports break down profitability by channel.

Automation handles picking and packing. It unifies POS and online workflows. Growing businesses add warehouses easily. The setup includes data migration help. Focus stays on sales, not spreadsheets. (96 words)

Zoho Inventory

Zoho Inventory is ideal for small to mid-sized distributors. Retailers in books, toys, and consumer goods pick it often.

Barcode and RFID scans accurately track items. Batch and serial numbers log details. Multi-channel sales draw from a single stock pool. Purchase orders automate vendor buys. Replenishments suggest restocks based on thresholds. Demand forecasting uses past data. Low-stock alerts ping via email.

Custom views filter reports. Integrations are available for Zoho CRM and QuickBooks. Users cut manual entry by half. Mobile app handles counts on the floor. Free tier suits startups. It grows with business needs. Data stays secure in the cloud.

Square for Retail

Square for Retail fits pop-ups and small shops. Gift stores, florists, and cafes use it daily. Built-in tracking updates stock per sale. Daily alerts flag low items.

Counting tools speed physical audits. Multi-location views show all branches. Sync with online stores prevents double sales.

Reports track top products and margins. Integrations add payroll and marketing. No monthly fees for basics. Hardware bundles include scanners. Setup runs in hours. It pairs with Square payments seamlessly. Scalable for chains too. Focus on customers, not back-end chores.

Simplify Inventory Management with KORONA POS Today

If you’re running a retail business, KORONA POS can help you simplify inventory management in a powerful yet easy way. You can manage all your products from one central catalog, track items in real time, and set automatic reorder levels so you never run out of stock. With barcode scanning, bulk edits, and shipment tracking, managing your shelves becomes faster and far less stressful.

You’ll also appreciate that KORONA POS offers dual pricing and is processing agnostic. You can set different price levels, like cash vs. card pricing, and choose any payment processor that fits your needs—without being tied to a single provider. This flexibility works great for liquor stores, vape shops, and multi-location retailers.

You can even handle stock counts right from your tablet, view low-stock alerts, and print labels instantly. Everything stays synced across locations, saving you time and keeping your team organized.

Sign up for a demo with one of KORONA POS’s product specialists or call 833-200-0213 today to get started.

FAQs: Slow-Moving Inventory

What is considered slow-moving inventory?

Slow-moving inventory refers to products that have not sold within a specified time frame. Retail businesses have different time frames that they consider to be appropriate for their stock to move off of the shelf. Generally, these windows are either 90, 120, or 180 days.

How can you reduce labor costs without cutting staff hours?

Increase the efficiency of your business by streamlining operations, implementing procedures, and uniform policies. These help delegate tasks to the right people and increase productivity among the team.

How can I lower payroll costs?

There are many ways to lower payroll, but for small businesses that pay staff at hourly rates, the easiest way to lower payroll is by reducing hours during slower times of the day. Use your sales reporting in your POS system to identify time frames where you can reduce your staffing.

What is non-moving inventory?

Non-moving inventory refers to stock that has not been sold or used for a significant period. It ties up capital and storage space.