Compliance is one of the key aspects of running any cannabis related business. State cannabis regulatory bodies require close monitoring of the entire process from cultivating plants to making the final sale at the dispensary. Often, this track and trace technology involves using radio frequency identification tags (RFID) for plants, packages, and products.

RFID is a great tool for keeping track of inventory in all types of marijuana enterprises. Not only does it help businesses stay compliant, reduce labor necessities, and increase inventory accuracy, but it also drives sales data that provides retail insights. Read on to learn more about RFID technology in cannabis.

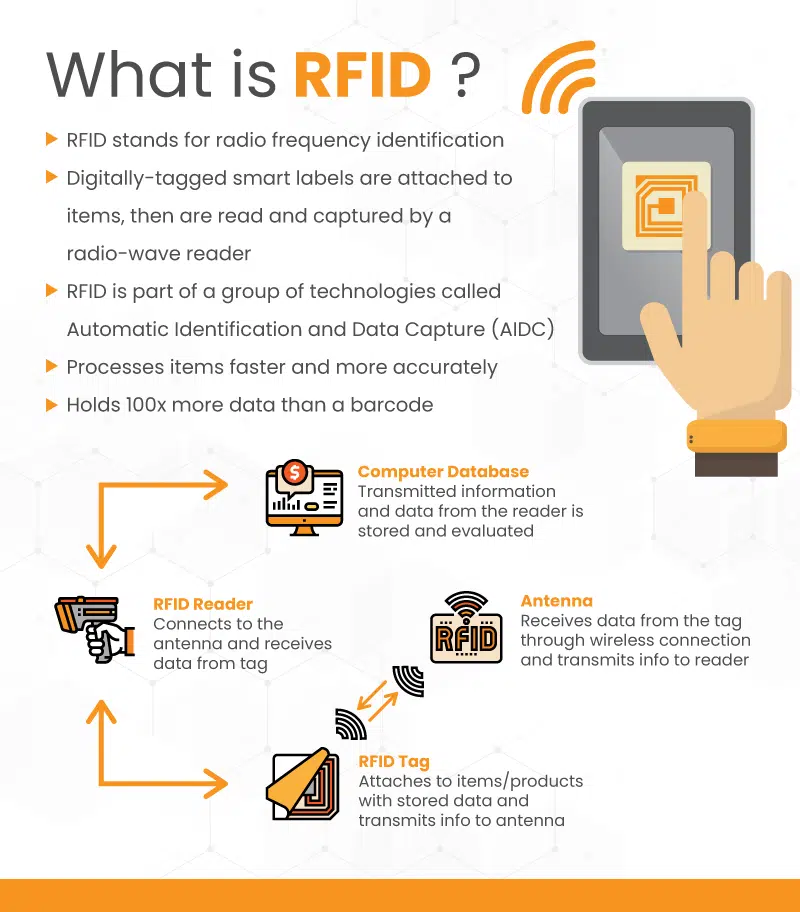

What is RFID?

RFID stands for radio frequency identification. It refers to digitally-tagged smart labels that are attached to items and then read and captured by a radio-wave reader. RFID is part of a group of technologies called Automatic Identification and Data Capture (AIDC).

This type of tagging is essentially an upgraded, more modern and versatile version of a barcode scanner. It can process items much faster and more accurately, streamlining operations. In fact, they actually hold as much as 100 times the amount of data than a 20 character barcode. An RFID reader are scans the tag, and then converts the data into usable information through a remotely-connected computer.

RFID Scanners

The price of handheld scanners that read RFID tags begins around $1,500. This price increases considerably as you get more features, range, and coverage. Some of the most expensive cutting-edge RFID readers cost tens of thousands. Remember, however, that your investment in streamlining and optimizing your efficiency and accuracy in managing inventory will cut considerable labor costs.

See related: RFID Implementation in the Retail Environment

How Is RFID Used In The Cannabis Industry?

As previously mentioned, cannabis is a highly regulated industry. State cannabis control bodies require data systems to monitor every cannabis product from seed-to-sale. They want to know exactly where every cannabis item is at every given moment.

Metrc’s RFID Technology

The biggest government track-and-trace reporting software in the country is Metrc. They are now contracted by 19 state governments, operating in Alaska, California, Colorado, Louisiana, Maine, Maryland, Massachusetts, Michigan, Missouri, Minnesota, Nevada, Ohio, Oklahoma, Oregon, West Virginia, and Washington D.C.

Metrc’s proprietary RFID technology helps power their whole system. The tagging of mature plants, bundles of products, and consumer retail goods ensures accurate and efficient reporting across the board. RFID helps eliminate the chances of cannabis products being diverted, stolen, or counterfeited. It also helps ensure that plants and products can be tracked down in the case of a product recall.

In the Metrc ecosystem, RFID tags are unfortunately single-use, meaning that cannabis businesses will have to continuously buy more of them for each plant and product they monitor. The good news is that Metric has an open API to integrate with dispensary inventory management tool and smart POS systems. This allows enterprises to automatically upload reports to the state, avoiding the complications and inaccuracies of manual entry.

RFID Tags For Cultivators

As soon as a plant reaches maturity, it must be entered into state compliance systems using individual RFID tags. Such tags are stuck directly into the plastic pots in which the cannabis plants grow. Each plant tag will store data, including a unique plant identification number, tag order date, and information indicating whether the plant is for medical or recreational use. It also provides details regarding the cultivation facility license number and name.

RFID technology provides multiple advantages for cultivators and growing operation workers. They eliminate any physical touching of the actual plant and are unaffected by dirt or soil covering barcodes since they read the digitized tags remotely.

There is an emerging type of RFID sensor that detects environmental factors like light and humidity, which will surely be an invaluable asset to cannabis production in the near future.

How Are RFID Tags Used By Dispensaries?

Wholesale items received by dispensaries in Metrc-compliant states will have RFID tags on their packaging. However, once these items are put into retail inventory, dispensaries are not required to use RFID tags. They can use traditional barcode or QR codes to scan into their system as long as they are keeping track of all of their sales and inventory in conjunction with Metrc.

However, using RFID technology provides significant advantages for cannabis retail businesses. This is true for multiple aspects of running a dispensary, and we will likely see more and more of their use in the future.

Inventory Check-In And Shipment Verification

RFID technology makes your inventory check-in effortlessly streamlined. Instead of having to search for every barcode to capture and input into your system, you can input dozens of items per minute by simply scanning across the general location of the received items with a fixed RFID reader.

Reduce time, effort, and errors through this means of processing incoming cannabis products. It also frees up labor costs so that you can have your team focus on other aspects of running your business.

Stock Counts

The accuracy of RFID eliminates human error and thwarts inventory inconsistencies that lead to theft, shrinkage, and non-compliance issues. Once you have those products in your inventory, RFID tech continues to make every item easier to find and account for. Whenever you need to do inventory counts to self audit and ensure compliance, the radio frequency capability will make this much less time and energy consuming.

Have near-expiration items or stagnant inventory you want to push out? Finding and reading information about each item in your stock will be that much faster and more consistent. You can even command an RFID reader to find expiring items within a specific room, pointing you exactly towards the items that you need to move off your shelves by promoting it for a sale or bundle.

Easier Delivery

This technology is also beneficial to dispensaries that operate in places where cannabis deliveries are permitted. Drivers can easily scan items out that are ready for home delivery, expediting the process of making sure that all of the items in the order are in the shopping bag. This eliminates extra time needed for fulfillment, allowing you to complete more orders in less time.

Full Visibility

The latest RFID technology allows for you to have full visibility of your complete inventory. Simply put, you will know where all of your different products are at all times, facilitating exact reconciliation counts to report to your track-and-trace system.

Additionally, RFID scans foster a more accurate and complete tracking apparatus. This precision enables you to keep a closer eye on your profitability, better understand your product performance, and analyze your overall performance.

KORONA POS has been a huge game changer for my overall profitability. Implementation was seamless and painless! The support staff is great and always ready to help. Had I known it would be this easy, I would have made the switch sooner!

-Kristen L.

KORONA POS Integration With Metrc

KORONA POS dispensary point of sale is fully integration ready with Metrc track-and-trace software. You can automatically push all of your inventory and sales data onto their state-required monitoring platform without the need for any manual entry or extra burden from compliance-related stress.

This point of sale and compliance set up, in conjunction with RFID scanning capabilities, offers the most optimized system for long term dispensary success. KORONA POS is competitively priced, with built-in industry-leading data analysis, cash control, and customer service. Give us a call today to schedule a demo!

FAQs: The Cost of Opening a Dispensary

RFID technology is used for searching and tracking items and people. They are essentially upgraded barcodes that carry significantly more information. In retail, smart labels are fixed to products, and are later searchable and scannable with an RFID reader.

The leading industry that uses RFID technology is hospitals Here, it’s of the utmost importance to maintain accurate and efficient checking-in of patients and staff and constant monitoring of expensive equipment. However, this tech has expanded into many other industries such as retail, pharma, and even pets and livestock. Since cannabis was legalized, RFID tech has been implemented by Metrc, the biggest government-facing track-and-trace monitoring system.

The cannabis industry uses RFID tags primarily to monitor marijuana products from seed-to-sale. State-regulated track-and-trace systems, like Metrc, ensure compliance with RFID technology to follow all cannabis products, from their time as a seed all the way through the final sale at a cannabis retail location. There is an increasing amount of RFID use in dispensaries to efficiently audit inventory, as well as to accurately track sales, and push data onto state compliance software.

One of the disadvantages of RFID technology is that it is expensive, both in terms of the cost of ordering tags and acquiring the high-quality scanners themselves. In addition, there are some complications that can arise using RFID tags, such as interference from metal objects and water. However, as the technology progresses we are likely see the overall price go down and accuracy go up.