Streamlining and optimizing your inventory management is necessary for even the smallest retailers. Some of you may not need more advanced features, like stock transfers or store orders, but everyone needs basic counts and SKU management.

Inventory management wouldn’t be possible without the barcode. This clever invention allows merchants to seamlessly track all products from entering your store until they’re paid for and go out your door. It’s truly remarkable for both its simplicity and effectiveness.

But there’s a bit more to them than initially meets the eye. Barcodes differ from SKUs and UPCs. And there are various types. Plus, you might not know all of their interesting benefits. We’ve compiled this FAQ guide to help you navigate barcodes and how they can be implemented at your retail store.

What Is a Product Barcode?

The barcode was invented in 1951 by Norman Joseph Woodland and Bernard Silver. Their inspiration came from Morse code, extending dots and dashes into thick and thin bars.

Despite not achieving much commercial success for several decades after its invention, the structure and function of the barcode have remained relatively unchanged. It still features an array of black lines of varying degrees of thickness. These are accompanied by a set of numbers below them.

Barcodes began to be used commercially in the early 1970s after George Laurer altered the original circular design to be horizontal and, thus, more easily read by a scanner. The parallel black lines separated by white could be easily scanned to facilitate checkout or inventory management operations. In 1974, a pack of chewing gum became the first product ever scanned with a UPC code.

The technology has evolved to QR codes and automatic identification and data capture (AIDC), though these systems also maintain the simplicity that made the barcode such a success.

How Do Barcodes Work?

Each barcode has a unique combination of lines. Any given combination encodes certain information about a product. This information can then be translated into actual text that appears on a digital screen.

Additionally, this information is sent to a POS device that can attach further information once it’s scanned. For instance, the barcode contains the product name. And once scanned, the POS machine pulls up the pricing, description, matrix, and more. If the barcode contains the product UPC, it also holds manufacturer information. Barcodes with SKUs, on the other hand, hold only internal product information.

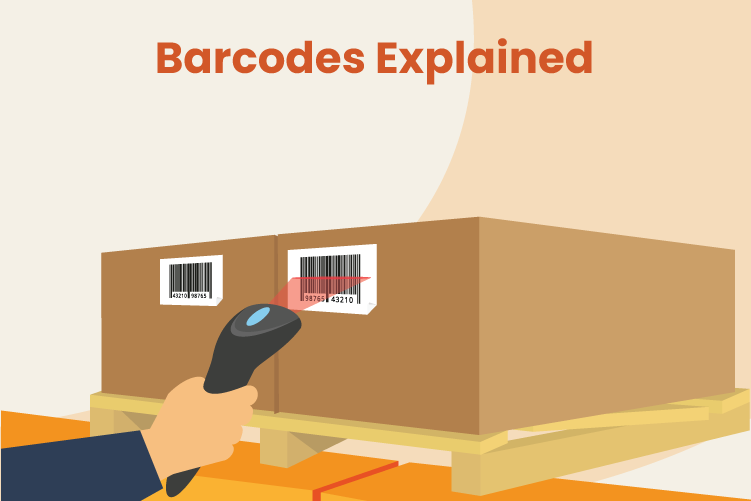

What Are the Benefits of Barcodes?

Barcodes are a critical tool for nearly every retail business. Aside from facilitating transactions, they offer several other key benefits.

Great Inventory Management

First and foremost, barcodes make inventory management much MUCH easier. Combine the scanning technology with your POS and reporting systems, and you’ll get significant insight into your products and their performance.

Learn how to manage your inventory effectively with this free eGuide.

More Accuracy

With barcode scanners, there is much less room for small clerical errors. With improved accuracy, you’ll also improve your ordering, costing, pricing, promotions, and loss. Choosing the best POS system with barcode scanners is important to streamline your store operations.

Ease of Use and Implementation

Overall, implementing a system of barcodes is remarkably easy, especially compared to some of the other projects the average business owner has to deal with. Data migration takes minutes, and creating new UPCs and SKUs in your point of sale is straightforward and can be done in bulk.

Data in Real-Time

You’ll also get more insight into your business with real-time data. As soon as a barcode is scanned into your inventory or a sale is made, that change is reflected in the system’s backend. This notifies you when stock is low, connects to other sales channels so you don’t sell something you don’t have in stock, and even communicates with suppliers for automated reordering.

The Technology Won’t Be Dated

There’s a reason barcodes have hardly changed in 50 years: they work. And even though the technology has evolved in more recent years to add QR codes and SKUs, the root of it and the associated hardware haven’t changed. It’s an investment that will last.

It’s Scalable

Businesses can also easily expand their operation to multiple locations or franchises. All barcode data can be transferred to a new location, minimizing the time and cost of growing your business.

Lower Overhead Costs

Finally, it saves time, lowering your overhead costs. There is no longer a need for a full-time inventory manager or stock person. Plus, it automates several other processes, saving you even more time and money.

Are There Different Types of Barcodes?

To process a barcode, it needs to be scanned. Scanners come in many shapes and sizes, but their job is to read and transport the barcode information to the appropriate system. These help retailers maintain great efficiency and accuracy by creating a seamless channel for data entry into their POS software.

For retailers, this means sending the barcode information to the point of sale system. Most merchants will use one or multiple types of scanners listed below: 1-D scanners, 2-D scanners, and alphanumeric codes.

1-Dimensional Scanners (1-D)

These scanners read simple barcodes on flat surfaces. They process less information since the codes get physically longer as more information is added.

Most 1-D scanners are the handheld “gun” model. These must be pointed directly at the barcode and usually don’t have omnidirectional scanning capabilities. The normal range is up to 2 feet.

2-Dimensional Scanners (2-D)

2-D codes hold a whole lot more information than 1-D. They can hold up to 2,000 characters but are smaller than a barcode. 2-D codes add squares, hexagons, dots, and other patterns instead of just using lines.

Additionally, 2-D scanners can process QR codes, so retailers can use these to scan smartphone screens, activate loyalty check-ins, upload images, connect to URLs, pull up menus, play voice recordings, and more.

These scanners come in many different models, but each can scan omnidirectionally, helping to facilitate a smoother checkout experience.

Alphanumeric

Either scanner can also pick up alphanumeric codes for SKUs. Not every retailer will need them to do this, but bigger operations that need more product segmentation will benefit from creating alphanumeric SKUs in addition to the standard UPCs.

What Is a UPC?

Short for universal product code, a UPC is an identifying code printed on retail items. It consists of black bars that can be scanned as well as a 12-digit numeric code underneath.

UPCs, as the name suggests, are universal across all retailers. It was created to simplify and speed up the ordering, inventory, and checkout process.

The first 6 digits of a UPC are used to identify the individual manufacturer. Therefore, every product from a certain manufacturer will have the same first 6 digits. The next 5 digits are used to identify the individual product. Each unique size, color, shape, etc., will get its own 5 digits. Finally, the last digit is used to check the entire code’s authenticity and ensure that the item rings up correctly at the checkout. This is often referred to as the check digit.

Additionally, you might see a difference in UPC sizes. While the 12-digit code is standard, there is a shortened version of the code that some retailers use to simplify their inventory. UPC-A refers to the standard length code. The alternative code, or UPC-E is shortened by compressing unused zeros at the end of the manufacturer code or the beginning of the product code.

Any manufacturer must apply with the Global Standards Organization for a new UPC.

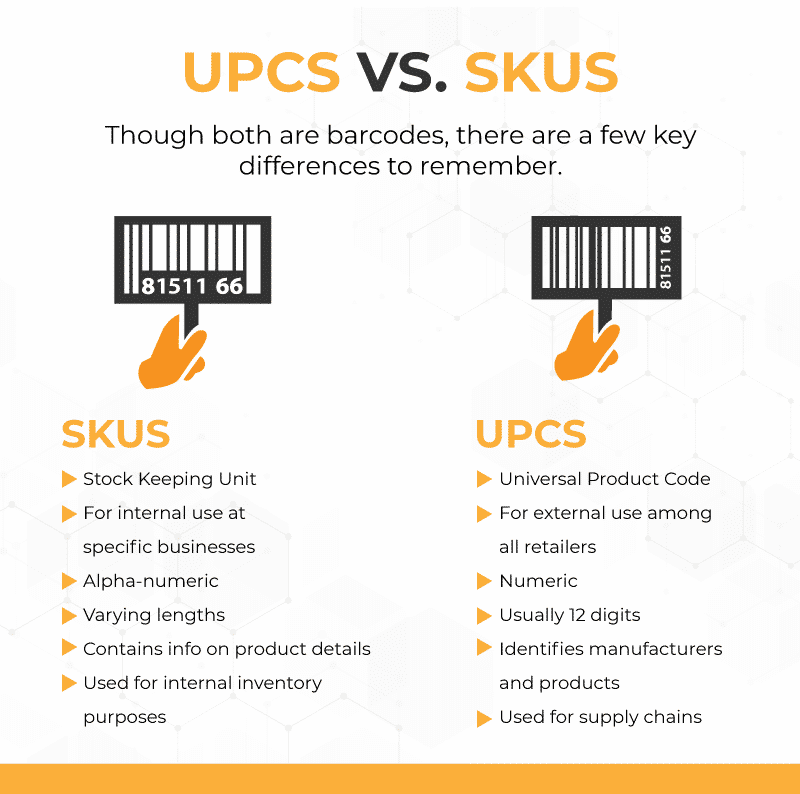

What’s the Difference Between a UPC and an SKU?

Most importantly, a UPC is universal across all retail locations, while an SKU is only used internally within a single company. So a product sold by multiple businesses will have only one UPC but multiple SKUs.

SKUs are used to help businesses track inventory. They are alphanumeric codes that can be printed on a unique label or attached to the UPC.

SKUs are not necessary for every retailer. Only those that need more in-depth product reporting will benefit from creating SKUs. Think of it as a supplement to UPCs.

For more information on implementing UPCs and SKUs through your point of sale software, click below. KORONA POS has the best retail inventory management software on the market. With a free trial, we’ll upload your existing product line into your account so you can see exactly how your SKUs and UPCs will work. Click below to get started.