Imagine running a bustling retail store where keeping track of inventory and managing your assets is a daily challenge. In this scenario, you’ve probably faced the headache of lost items or inefficient tracking systems again and again.

Enter the debate between radio frequency identification (RFID) vs. barcodes—two inventory tracking systems that have revolutionized how we handle inventory and streamline operations.

This guide will delve into the differences between RFID and barcoding technologies and their advantages and drawbacks to help you decide which system best suits your inventory management needs. By the end, you’ll be fully equipped and confident to make streamline your inventory process for good.

Key Takeaways:

- RFID uses radio waves to transmit data and does not require direct line-of-sight.

- Barcodes are optical and require a scanner aimed directly at the code on individual items.

- RFID is ideal for environments needing fast, automated data capture, while barcodes are cost-effective and widely used.

- Both systems have unique pros and cons, making them ideal for different applications.

The Differences Between RFID and Barcodes

Despite being both inventory tracking technologies, RFID and barcodes operate fundamentally differently. Understanding these distinct differences empowers you to make an informed decision that best meets your business needs. Let’s get started!

What is RFID?

RFID uses radio waves to read and capture information stored on tags attached to objects. There are two types of RFID tags: passive (no battery) and active (battery-powered).

Unlike barcodes, RFID tags do not require direct line-of-sight. Therefore, systems can read and transmit data from tags without needing a clear, unobstructed view between the tag and the reader.

With its ability to efficiently read and transmit data from afar, RFID is a game-changer for environments that require scanning from a distance. It’s especially beneficial for real-time inventory management and item tracking.

What is a Barcode?

A barcode is a visual pattern of parallel lines and spaces representing data. There are many types of barcodes, most using black bars and white lines of different widths to create a character or number. The technology is pervasive—barcodes are on items at grocery stores and retail operations worldwide.

How do barcodes work, you ask? Barcode scanners (laser or CCD) decode data, translating the information into readable text or numbers using laser or light sensors.

Barcode readers require a direct line of sight for scanning and function in a wide range of applications for product identification and inventory management.

RFID vs. Barcodes: How to Choose

Choosing between RFID and barcoding largely depends on your business’s needs and operational environment. When deciding between RFID and barcoding, consider the following factors:

- Budget: It always comes down to budget. RFID systems generally involve higher upfront costs for tags and readers than barcodes. For budget-conscious operations, barcodes offer a cost-effective solution with lower upfront investment.

- Scanning Requirements: If your business requires high-speed, automated scanning with the ability to read multiple tags simultaneously, opt for RFID. If you’re running an operation where manual scanning is feasible, barcodes should do the trick.

- Operational Environment: RFID is ideal for environments with high inventory turnover, automated processes, or wherein real-time tracking of high-value supply chain assets is critical, like hospitals or cannabis operations. Conversely, barcodes work in retail settings where smaller amounts of inventory move, and manual scanning is feasible.

Inventory management headache?

KORONA POS makes stock control easy. Automate tasks and get a clear picture of your entire inventory.

RFID: Pros and Cons

We’ve touched on this already: RFID can revolutionize and automate your inventory management operations depending on your business but at a cost. Let’s get into the pros and cons of RFID:

Pros

- More Efficient: Implementing RFID unlocks the ability to scan many things simultaneously. This time-saving, automated feature can help everyone from medical assistants to manufacturers account for hundreds of items in just a few moments, all through radio waves (it’s a super-technology for efficient warehouse management, for example).

- Inventory Control: RFID data collection allows users to keep detailed track of individual products, regardless of whether or not they are visible. It’s a valuable tool for finding the precise location of assets, provided the RFID tag remains in place.

- Higher Data Capacity: Another benefit of RFID tags is they can store significant information beyond an identifier, including details about an item or its history. Therefore, these systems provide more comprehensive inventory tracking and asset management information.

Cons

- Higher Initial Costs: RFID systems are much more expensive to set up than barcode systems, with significant costs associated with tags, readers, and software. The steep initial investment might be prohibitive for businesses with limited budgets.

- Security Concerns: RFID scanners read tags without direct contact, so some worry about potential unauthorized access to sensitive data. Businesses must implement proper RFID security measures to protect against data breaches.

- Complex Integration: Integrating RFID systems with existing inventory management software can be tricky. Doing so might require technical expertise, additional training, and ongoing support, possibly costing your business even more money.

- Signal Strength: RFID tags are susceptible to signal breaks, especially in harsh environments where lots of metal or water are present. Its reliability depends on environmental conditions that don’t interfere with RF.

Barcodes: Pros and Cons

Let’s pivot to barcodes—they offer many advantages over RFID, assuming your business’s budget and operations align with barcoding solutions. For some operations, however, barcoding falls short. Here are the pros and cons of barcodes:

Pros

- Affordable: Barcode labels and scanners are inexpensive, making them the most straightforward option for lower-budget retail operations.

- Ease of Use: Scanning barcodes is almost effortless. You find one on the tag or product packaging, scan it, and the data translates to your POS or inventory management system. Nowadays, you can even use mobile devices like your smartphone to scan barcodes and QR codes.

- Widespread Technology: Many items already have barcodes, saving your business time and money. If they don’t, you can quickly generate a custom barcode, print it on a sticky label, and paste it on your inventory item.

Cons

- Uniform: Every item of the same type in your inventory will likely have the same barcode, making it harder to pinpoint inventory. You can always generate a unique barcode for high-value items to make tracking easier.

- Less Efficient: You can only scan one barcode at a time and only when the barcode is completely visible, which limits how quickly your employees can check inventory in and out.

- Limited Data Storage: Barcodes encode information in a simple pattern of black lines and spaces, restricting the amount of data one can store and track. They can only hold primary identifiers like product numbers and cannot store extensive information like RFID tags can.

RFID vs. Barcodes in Practice

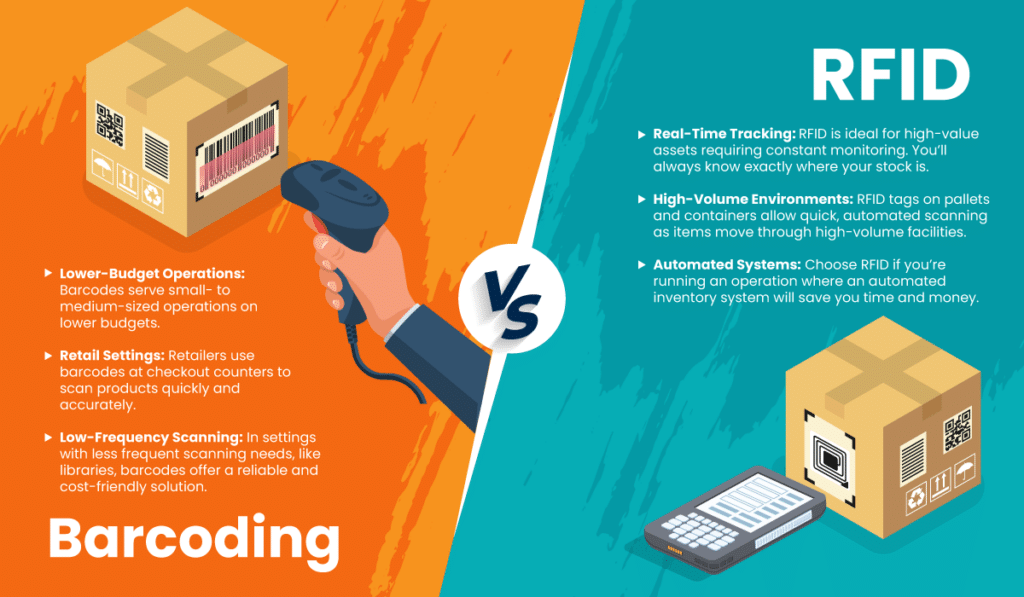

Let’s examine the two technologies in action to better understand which settings and scenarios they make the most sense in. The graphic below demonstrates some real-life use cases of RFID vs. barcodes:

Is Barcoding or RFID Better?

It’s difficult to say which is better when deciding between barcoding and RFID—the answer depends entirely on your budget and specific operational needs.

Barcoding is cost-effective for environments with lower item turnover and less frequent scanning requirements (like small retail stores or libraries). On the other hand, RFID shines in high-volume environments where automated, rapid scanning is crucial, such as large warehouses and distribution centers, albeit at a much higher cost.

Ultimately, the choice between RFID vs. barcodes depends on your budget, scanning needs, and operational environment. Whatever you do, choose an inventory management system that best aligns with your longer-term goals—having a POS system that integrates with both is a great place to start.

Speak with a product specialist and learn what KORONA POS can do for your business.

Frequently Asked Questions

RFID tags come in two main types: passive and active. Passive tags lack a battery and rely on the RFID reader to power them, while active tags have their own battery, allowing them to transmit signals over longer distances.

Generally, RFID is better for environments that require fast, automated, and high-volume scanning with no line-of-sight needed. However, barcodes are more cost-effective and straightforward for operations with tighter budgets and lower scanning demands.

RFID can replace barcodes in scenarios that require enhanced efficiency and data capacity. Because barcodes are so universal (and economical), it’s unlikely RFID will ever fully replace them.

RFID systems typically involve higher upfront costs for tags, readers, and software, ranging from $5,000 to more than $100,000 to implement. Conversely, barcodes are much more affordable, making them a budget-friendly option for many businesses.

Final Thoughts

Choosing between RFID and barcoding hinges on your business’s needs, budget, and operational environment. While RFID offers advanced high-volume and real-time product tracking features, barcodes are the time-tested, budget-friendly solution for more straightforward, lower-volume applications.

Explore KORONA POS and our inventory management resources for more detailed insights and solutions tailored to your needs.