Key Takeaways:

- Properly categorizing and classifying items reduces search times, minimizes errors, and optimizes workflows.

- Maximizing space through vertical storage solutions, efficient shelving systems, and clear labeling enhances warehouse organization, order fulfillment speed, and inventory management.

- Investing in technologies such as RFID and barcode systems automates processes and provides real-time data for better decision-making.

Efficient inventory management is crucial for the success of any retail warehouse operation. An organized inventory facilitates smooth day-to-day operations, enhances overall productivity, reduces errors, and ensures customer satisfaction.

This guide will explore the key principles and strategies to help you effectively organize inventory in a warehouse, maximizing space utilization and streamlining inventory management processes.

1. Categorization and Classification

One of the fundamental steps in organizing warehouse inventory is to categorize and classify items. Establishing a well-defined categorization and classification system streamlines the storage of goods and facilitates efficient retrieval processes.

By grouping items with shared traits, warehouse personnel have reduced search times, minimized errors, and optimized overall workflow. Strategic product placement based on warehouse demand patterns also enhances accessibility. This practice ensures that high-demand items are easily accessible for timely order fulfillment.

ABC Analysis

Many retailers utilize a systematic approach such as ABC analysis. This technique prioritizes items based on importance.

High-value items with lower frequency are classified as A, requiring close monitoring and careful management. B items, with moderate value and frequency, receive intermediate attention. In contrast, C items, representing low-value, high-frequency items, are managed with more automated and streamlined processes, allowing warehouse managers to allocate resources efficiently and optimize inventory control. The best retail management software solutions make this easier.

“We made a commitment to smarter organization, categorization, and placement of items. With a couple of tweaks and reconsiderations, these adjustments have increased our warehouse efficiency immensely – oh, and our profitability too!”

Phil K – Pine Tree Bottle Shop

2. Space Utilization and Optimization

Maximizing the use of available space is crucial in warehouse organization. Consider vertical storage solutions, such as mezzanines or high-density storage systems, to maximize warehouse height.

Implement a slotting system that places fast-moving items closer to packing and shipping areas. This can greatly improve warehouse efficiency and order fulfillment speed.

Better Shelving

The efficient implementation of shelving systems is a cornerstone in warehouse optimization. Shelving units designed for smaller items offer a tailored solution for products of varying dimensions, such as electronics or small parts.

Unit flexibility, such as adjustable shelves, can be a great asset as retailers evolve their merchandising. Building a dynamic, adaptable storage environment will help accommodate inventory size and composition fluctuations.

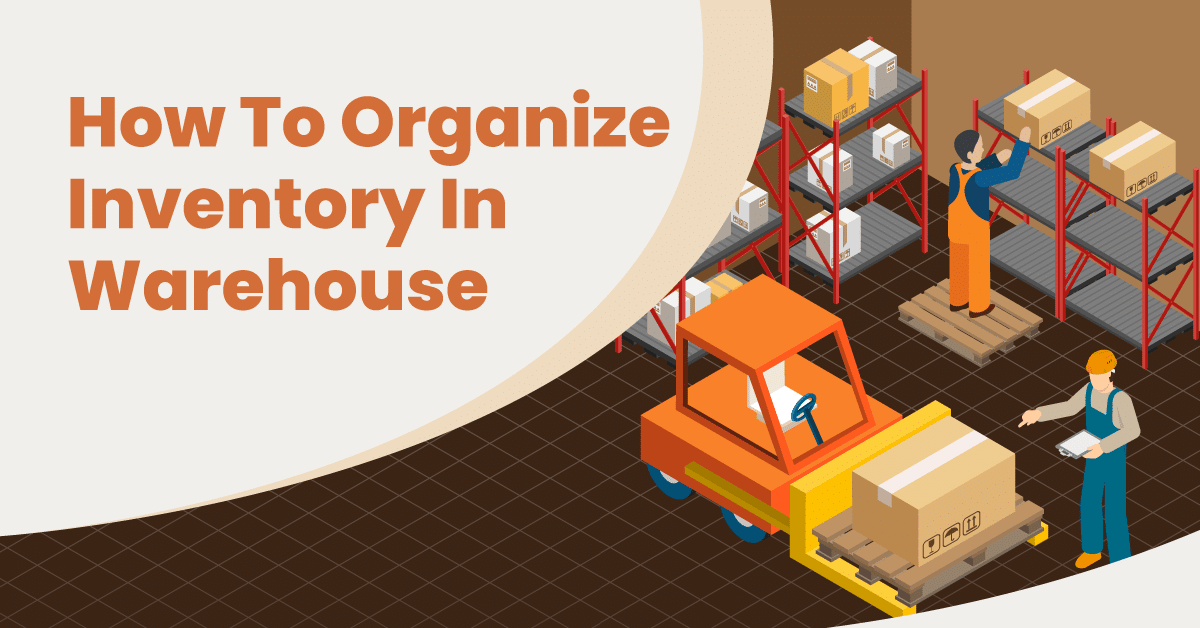

Labeling

Clear and precise labeling further complements the efficacy of shelving systems. Each section should be prominently labeled, allowing for easy visual identification of stored items.

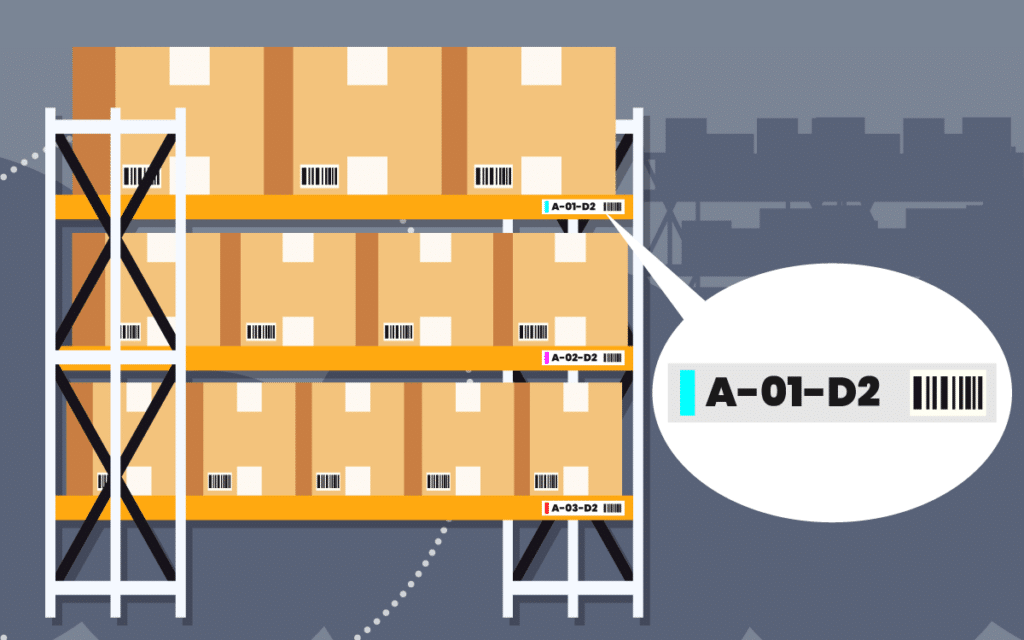

Implementing advanced labeling techniques, such as RFID tags, facilitates automated tracking and inventory management. This reduces the margin for human error and enhances the speed and accuracy of order fulfillment.

3. Utilize Software Solutions

Investing in advanced inventory management technologies is a game-changer for organizing warehouse inventory. These systems automate various processes, including order processing, stock tracking, and reordering, making it easier to tackle common inventory management obstacles.

Barcode and RFID technology can be integrated with various types of software to enhance accuracy and reduce the likelihood of errors. The real-time data these systems provide allows for better decision-making and ensures that inventory levels are always up-to-date.

RFID For Warehouse Optimization

RFID technology is a powerful tool for warehouse optimization, revolutionizing inventory management. RFID scanners are operated using a technology with radio waves to wirelessly identify, track, and locate products equipped with RFID tags or labels.

By incorporating RFID tags on products, warehouse managers can achieve real-time visibility into the movement and location of items throughout the facility. This technology enhances accuracy in tracking and reduces the risk of errors associated with manual data entry.

RFID For Warehouse Optimization

RFID technology is a powerful tool for warehouse optimization, revolutionizing inventory management. RFID scanners are operated using a technology with radio waves to wirelessly identify, track, and locate products equipped with RFID tags or labels.

By incorporating RFID tags on products, warehouse managers can achieve real-time visibility into the movement and location of items throughout the facility. This technology enhances accuracy in tracking and reduces the risk of errors associated with manual data entry.

Automatic Reordering

In one survey, 67% of businesses said they lost customers due to product stockouts. Luckily, point of sale (POS) software with automatic reordering capabilities streamlines business inventory management. With this feature, the system monitors stock levels in real-time and automatically generates purchase orders or replenishment requests when inventory falls below predefined thresholds.

This ensures that businesses maintain optimal warehouse stock levels, minimizing the risk of stockouts or overstock situations.

Perpetual and Real-Time Inventory

Perpetual inventory systems maintain real-time stock level updates, enabling immediate inventory status visibility. This helps warehouse managers make informed decisions, preventing stockouts or overstock situations. By integrating perpetual inventory with advanced inventory management practices, such as demand forecasting and order optimization, warehouses can streamline processes.

The combination of perpetual inventory tracking and strategic inventory management enhances responsiveness and ensures a lean and agile warehouse operation.

4. Invest in Training and Education

In addition to ongoing training on inventory management techniques, incorporating specialized education programs can further empower warehouse staff. Equip them with in-depth knowledge of the latest technological advancements in warehouse automation, RFID systems, and other cutting-edge tools.

Comprehensive training ensures a smooth adoption of new technologies and positions your workforce to leverage innovations for optimal warehouse efficiency. Moreover, emphasizing safety protocols in training programs fosters a secure work environment, reducing the risk of accidents and minimizing disruptions.

Investing in continuously developing your team’s skills and knowledge creates a workforce adept at handling current warehouse challenges.

Establish Standard Operating Procedures

Part of the staff training and education should include creating and implementing clear Standard Operating Procedures (SOPs). SOPs are vital for maintaining consistency in warehouse operations. These procedures should cover receiving, storage, picking, and shipping processes.

Consider putting all of the information and policies into a notebook or PDF. Clearly defined procedures minimize errors, reduce training time for new staff, and create a more organized and efficient working environment.

5. FIFO and LIFO Inventory Strategies

There are two main inventory strategies to consider when organizing warehouse inventory: First-In First-Out (FIFO) and Last-In First-Out (LIFO). According to Forbes, about 55% of businesses use FIFO, while 15% use LIFO. The remaining combine those two or incorporate one of the many more niche inventory control methods, like the average cost method.

Choosing between FIFO and LIFO strategies is pivotal in enhancing efficiency and minimizing costs. Here is some more information about each of these options.

FIFO (First-In, First-Out)

Implementing the FIFO strategy is imperative when dealing with perishable or time-sensitive goods. In this method, the oldest inventory items are the first to be picked and shipped. This approach aligns with ensuring that products with earlier expiration dates or production dates are utilized first.

By adhering to FIFO, warehouses significantly reduce the risk of spoilage, expiration, or obsolescence of goods. This traditionally applies to c-stores, grocery stores, beer distributors, and even CBD shops.

One of the key advantages of FIFO lies in its ability to enhance product quality and customer satisfaction. By delivering fresher products, businesses can build and maintain a positive reputation in the market.

Additionally, FIFO simplifies inventory management by organizing goods chronologically, making tracking and rotating stock easier.

LIFO (Last-In, First-Out)

Conversely, the LIFO inventory strategy may be more suitable for non-perishable goods or industries where inventory costs fluctuate. In a LIFO system, the newest items are the first to be picked and shipped. This approach is often employed to optimize storage space and minimize handling costs.

LIFO can be advantageous in scenarios where prices of goods are rising. By first selling the most recently acquired inventory, businesses can offset taxes by matching higher-priced goods with higher revenue. However, it’s essential to note that LIFO may lead to reduced product quality over time, especially for items stored for extended periods (hence why it’s best for non-perishable items).

Choosing between FIFO and LIFO depends on various factors, including the nature of the products, market demands, and regulatory requirements. Some industries may even adopt a combination of both strategies, known as a hybrid approach, to balance the advantages of each method.

6. Monitor and Adapt

Implementing a robust monitoring system involves tracking KPIs and regularly analyzing the data to gain actionable insights. By scrutinizing metrics such as order fulfillment time, accuracy, and inventory turnover, warehouse managers can pinpoint areas for enhancement and fine-tune operational processes.

Embracing a culture of adaptability is crucial; stay attuned to changing business needs, market trends, and emerging technologies. Allow for swift adjustments in strategies, ensuring that the warehouse remains agile and responsive to the dynamic demands of the supply chain.

Furthermore, utilizing point of sale data illuminates the efficiency of warehouse strategies. This commitment to continuous monitoring and adaptation establishes a proactive approach to warehouse management, fostering long-term efficiency and competitiveness.

Conclusion

Effectively organizing inventory in a warehouse is a multifaceted process that involves strategic planning, technology integration, and a commitment to continuous improvement. By implementing the principles outlined in this guide, businesses can enhance efficiency, reduce costs, and ultimately deliver better customer service.

KORONA POS offers cutting-edge, dynamic inventory management. The software is designed to take on even the most complex product lists across many verticals.

To learn more about organizing inventory with KORONA POS, click the link below!

FAQs: How To Organize Inventory In Warehouse

To keep track of inventory in a warehouse, businesses employ various methods, such as implementing a robust inventory management system that utilizes barcoding or RFID technology to track items in real-time. Regular cycle counting and periodic physical inventory checks are conducted to reconcile actual stock levels with recorded data, thereby ensuring the most accuracy. Additionally, continuous monitoring of key performance indicators contributes to effective inventory tracking and management in a warehouse setting.

The best way to organize product inventory is through a systematic categorization and classification system. Grouping similar products based on common characteristics such as size, weight, type, or demand allows for efficient storage and retrieval processes. Additionally, adopting advanced inventory management techniques, like ABC analysis, prioritizes high-value items, ensuring strategic allocation of resources and optimizing overall warehouse efficiency.

The most popular inventory method widely used by businesses is the FIFO (First-In, First-Out) method, where the oldest inventory items are sold or used first. This method aligns with sound financial and tax practices and is especially crucial for industries dealing with perishable goods. FIFO ensures that goods with earlier acquisition or production dates are consumed first, minimizing the risk of spoilage obsolescence and reducing holding costs.