Key Takeaways:

- A barcode is a visual representation of data. It encodes information into a pattern of black bars and white spaces.

- Barcode scanners shine a light (often a red laser) onto the barcode. The dark bars absorb the light, while the white spaces reflect it.

- The electrical signal generated by the reflected light is converted to a binary code (a sequence of 0s and 1s) and then decoded into a string of numbers or letters.

Even the smallest retailers need to streamline and optimize their inventory management. Some may not need more advanced features, like stock transfers or store orders, but everyone needs basic counts and SKU management.

Inventory management wouldn’t be possible without the barcode. This clever invention allows merchants to seamlessly track all products from entering their store until they’re paid for and leave. It’s truly remarkable for its simplicity and effectiveness.

But there’s a bit more to them than initially meets the eye. Barcodes differ from SKUs and UPCs. And there are various types. Plus, you might not know all of their interesting benefits. We’ve compiled this FAQ guide to help you navigate barcodes and how they can be implemented at your retail store.

What Is a Barcode?

Norman Joseph Woodland and Bernard Silver invented the barcode in 1951. Their inspiration came from Morse code, which extended dots and dashes into thick and thin bars.

Despite not achieving much commercial success for several decades after its invention, the structure and function of the barcode have remained relatively unchanged. It still features an array of black lines of varying degrees of thickness and a set of numbers below them.

Barcodes began to be used commercially in the early 1970s after George Laurer altered the original circular design to be horizontal and, thus, more easily read by a scanner.

The parallel black lines separated by white could be easily scanned to facilitate checkout or inventory management operations. In 1974, a pack of chewing gum became the first product ever scanned with a UPC code.

The technology has evolved to QR codes and automatic identification and data capture (AIDC), though these systems also maintain the simplicity that made the barcode such a success.

Step-by-Step Guide to Creating Barcodes for Your Business

Are There Different Types of Barcodes?

A barcode needs to be scanned to process it. Scanners come in many shapes and sizes, but their job is to read and transport the barcode information to the appropriate system. They help retailers maintain great efficiency and accuracy by creating a seamless channel for data entry into their POS software.

For retailers, this means sending the barcode information to the point of sale system. Most merchants will use one or multiple types of scanners listed below: 1-D scanners, 2-D scanners, and alphanumeric codes.

1-Dimensional Scanners (1-D)

These scanners read simple barcodes on flat surfaces. They process less information since the codes get physically longer as more information is added.

Most 1-D scanners are the handheld “gun” model. These must be pointed directly at the barcode and usually don’t have omnidirectional scanning capabilities. The normal range is up to 2 feet.

2-Dimensional Scanners (2-D)

2-D codes hold a whole lot more information than 1-D. They can hold up to 2,000 characters but are smaller than a barcode. 2-D codes add squares, hexagons, dots, and other patterns instead of just using lines.

Additionally, 2-D scanners can process QR codes, so retailers can use these to scan smartphone screens, activate loyalty check-ins, upload images, connect to URLs, pull up menus, play voice recordings, and more.

These scanners come in many different models, but each can scan omnidirectionally, helping to facilitate a smoother checkout experience.

Alphanumeric

Either scanner can also pick up alphanumeric codes for SKUs. Not every retailer will need them to do this, but bigger operations that require more product segmentation will benefit from creating alphanumeric SKUs in addition to the standard UPCs.

Build Your Own POS

Whether you run a retail store, café, or admissions booth, we have the point of sale hardware designed for your specific needs. Start building your ideal POS system now.

How Do Barcodes Work?

Each barcode has a unique combination of lines. Any given combination encodes certain information about a product, which can then be translated into text on a digital screen.

Additionally, this information is sent to a POS device that can attach further information once it’s scanned. For instance, the barcode contains the product name.

And once scanned, the POS machine pulls up the pricing, description, matrix, and more. If the barcode contains the product UPC, it also holds manufacturer information. Barcodes with SKUs, on the other hand, hold only internal product information.

What Do the Numbers Mean on a Barcode?

The numbers on a barcode, typically a 12-digit UPC (Universal Product Code), are a unique identifier for a specific product. Each section of the number has a distinct meaning, acting as a key that allows a point-of-sale system or inventory database to retrieve detailed product information. They don’t contain the price or description but serve as a lookup code.

A standard 12-digit UPC barcode is divided into three main sections:

- The Manufacturer’s Identification Number: The first six numbers of the UPC identify the product’s manufacturer. A unique manufacturer code allows retailers and suppliers to track goods and manage a supply chain efficiently.

- The Product’s Identification Number: The manufacturer assigns the next five numbers to identify a specific product. For example, a single manufacturer might use different product codes for a product that comes in different sizes, colors, or flavors.

- The Check Digit: The final digit is a check digit used for error detection. It’s a single number calculated using a special algorithm based on the first 11 digits of the code. When a scanner reads the barcode, it performs the same calculation to confirm the code was scanned correctly. If the calculated check digit doesn’t match the one on the barcode, the scanner knows there was a reading error and will not accept the scan.

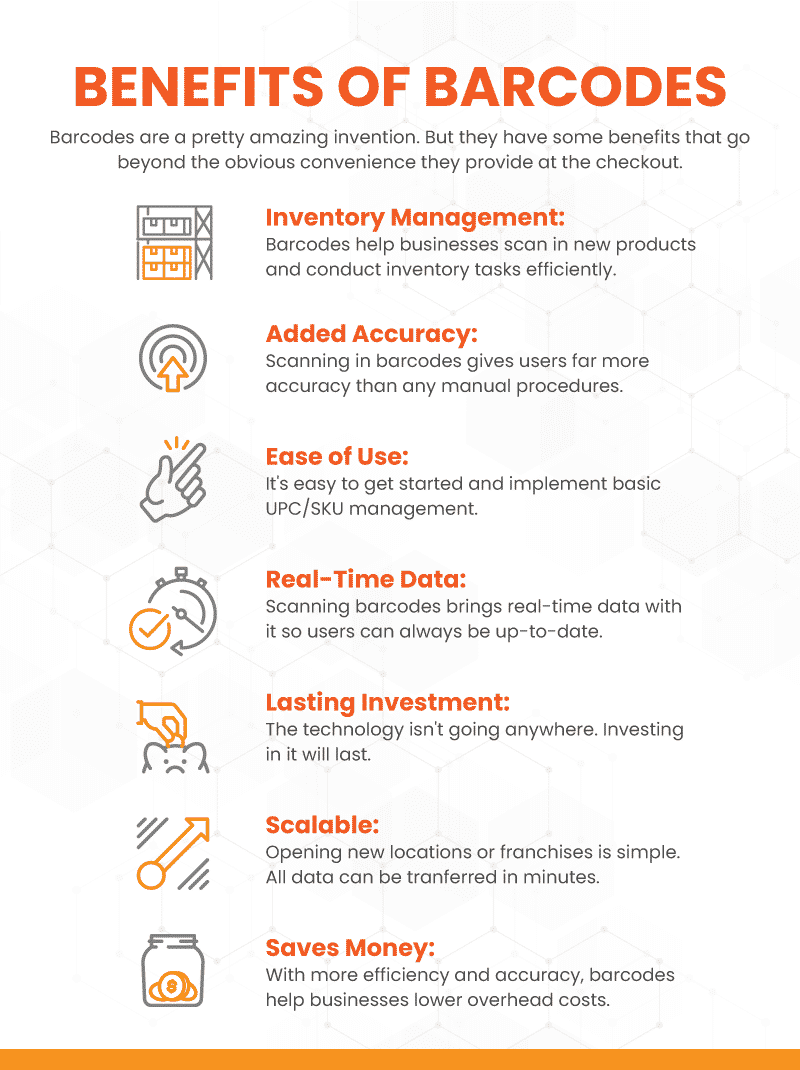

What Are the Benefits of Barcodes?

Barcodes are a critical tool for nearly every retail business. In addition to facilitating transactions, they offer several other key benefits.

Great Inventory Management

First and foremost, barcodes make inventory management much, much easier. Combine the scanning technology with your POS and reporting systems, and you’ll gain significant insight into your products and their performance.

Inventory management a headache?

KORONA POS makes stock control easy. Automate tasks, generate custom reports, and learn how you can start improving your business.

More Accuracy

With barcode scanners, there is much less room for small clerical errors. With improved accuracy, you’ll also improve your ordering, costing, pricing, promotions, and loss. Choosing the best POS system with barcode scanners is important to streamline your store operations.

Ease of Use and Implementation

Overall, implementing a system of barcodes is remarkably easy, especially compared to some of the other projects the average business owner has to deal with. Data migration takes minutes, and creating new UPCs and SKUs in your point of sale is straightforward and can be done in bulk.

Data in Real-Time

With real-time data, you’ll also gain more insight into your business. As soon as a barcode is scanned into your inventory or a sale is made, that change is reflected in the system’s backend. The system notifies you when stock is low, connects to other sales channels so you don’t sell something you don’t have in stock, and even communicates with suppliers for automated reordering.

Discover Advanced Analytics and Custom Reports

Speak with a product specialist and learn how KORONA POS can work for your business.

The Technology Won’t Be Dated

There’s a reason barcodes have hardly changed in 50 years: they work. Even though the technology has evolved in recent years to add QR codes and SKUs, the root of it and the associated hardware haven’t changed. It’s an investment that will last.

It’s Scalable

Businesses can also easily expand their operation to multiple locations or franchises. All barcode data can be transferred to a new location, minimizing the time and cost of growing your business.

Lower Overhead Costs

Finally, it saves time, lowering your overhead costs. There is no longer a need for a full-time inventory manager or stock person. Plus, it automates several other processes, saving you even more time and money.

Which Barcode Scanner Is Best for Your Business?

Selecting the right barcode scanner is crucial for any business aiming to improve efficiency, accuracy, and overall productivity. The “best” scanner isn’t a one-size-fits-all solution; it depends on your needs, environment, and budget. To make an informed choice, it’s essential to understand the different types of barcode scanners and their core technologies. Here is a breakdown of the most common types of barcode scanners, followed by guidance on choosing the right one for your business.

Pen-Type Readers

Pen-type readers, also known as wand scanners, are among the most basic and affordable types. They work by having the user manually drag the tip of the “pen” across the barcode. A light source and a photodiode at the tip measure the reflected light from the barcode’s bars and spaces, converting it into a waveform that is then decoded.

- Best for: Businesses with very low-volume scanning needs, such as small libraries or for personal inventory.

- Drawbacks: These scanners require a steady hand and uniform speed to be effective. They are slow, prone to user error, and cannot read damaged or poorly printed barcodes. They are generally considered outdated technology for most business applications.

Laser Scanners

Laser scanners are the most widely used type of barcode scanner. They use a laser beam that is rapidly swept back and forth across the barcode by a rotating mirror. The scanner then measures the reflected light, which is converted into an electrical signal and decoded.

- Best for: Retail point-of-sale (POS) systems, inventory management, and other applications where high-speed, accurate scanning of 1D linear barcodes is required. They are excellent at scanning from a distance and are generally faster and more reliable than pen-type readers.

- Drawbacks: Traditional laser scanners are limited to reading 1D barcodes. They may struggle with damaged or low-contrast codes.

CCD (Charge-Coupled Device) Readers

CCD readers, also known as LED scanners, use tiny light sensors (similar to a digital camera’s sensor) to take a “picture” of the barcode. The scanner then decodes the image. This technology measures the ambient light emitted from the barcode itself, rather than reflecting its own light source back.

- Best for: Retail and short-range scanning. They are more durable than laser scanners because they have no moving parts and are better at reading barcodes from screens (like a customer’s phone). They are also more forgiving with poorly printed barcodes.

- Drawbacks: They generally have a shorter scanning range than laser scanners and are limited to a certain width, meaning they may not be able to read very wide barcodes.

Camera-Based Readers (2D Imagers)

Two-dimensional imagers are the most advanced and versatile type of barcode scanner. They use a camera and advanced image processing technology to capture a full image of the barcode. This allows them to read both 1D and 2D barcodes (like QR codes and Data Matrix codes) from any angle or orientation.

- Best for: Businesses that need to scan various barcode types, including QR codes for loyalty programs or product information, and for applications in healthcare, logistics, and transportation. Their ability to read damaged or low-contrast barcodes and barcodes on screens makes them highly reliable.

- Drawbacks: They are generally more expensive than 1D laser or CCD scanners.

Omnidirectional Scanner

An omnidirectional barcode scanner can read barcodes from any angle. It uses a combination of lasers and mirrors or advanced imaging technology. Laser-based scanners use a single laser and a series of rotating or oscillating mirrors to create a complex, crisscrossing pattern of scan lines.

- Best for: Omnidirectional scanners are a top choice for high-volume environments where speed is critical, such as retail and grocery stores at the point of sale (POS), Warehouses, and logistics centers for inventory and order fulfillment, and hospitals and pharmacies for patient and medication tracking.

- Drawbacks: Omnidirectional scanners’ main drawbacks are their higher cost and power consumption, especially for the laser-based models, which have moving parts. They can also be less effective in reading barcodes with reflections or on highly curved surfaces, as the multiple scan lines can create confusing patterns. They are also more expensive than 1D laser or CCD scanners.

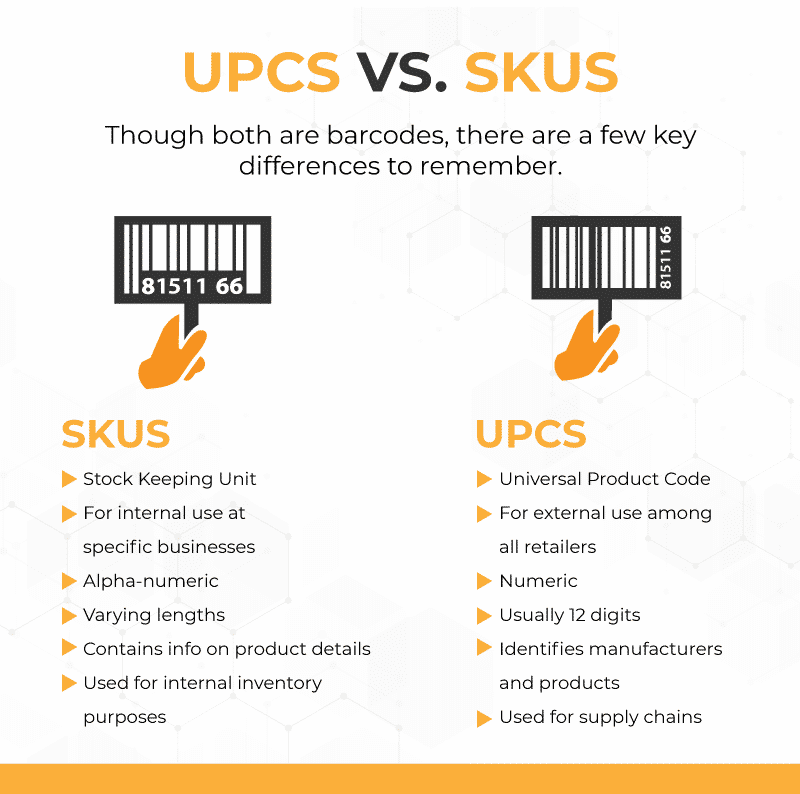

What Is a UPC?

Short for universal product code, a UPC is an identifying code printed on retail items. It consists of black bars that can be scanned and a 12-digit numeric code underneath.

As the name suggests, UPCs are universal across all retailers. They were created to simplify and speed up the ordering, inventory, and checkout process.

The first 6 digits of a UPC are used to identify the individual manufacturer. Therefore, every product from a certain manufacturer will have the same first 6 digits. The next 5 digits are used to determine the individual product. Each unique size, color, shape, etc., will get its own 5 digits. Finally, the last digit is used to check the entire code’s authenticity and ensure that the item rings up correctly at the checkout. This is often referred to as the check digit.

Additionally, you might see a difference in UPC sizes. While the 12-digit code is standard, there is a shortened version of the code that some retailers use to simplify their inventory. UPC-A refers to the standard length code. The alternative code, or UPC-E, is shortened by compressing unused zeros at the end of the manufacturer code or the beginning of the product code.

Any manufacturer must apply to the Global Standards Organization for a new UPC.

What’s the Difference Between a UPC and an SKU?

A UPC is universal across all retail locations, while an SKU is only used internally within a single company. So, a product sold by multiple businesses will have only one UPC and multiple SKUs. SKUs are alphanumeric codes that help companies track inventory. They can be printed on a unique label or attached to the UPC.

Ready to Use Barcodes Smarter? Try KORONA POS Today

KORONA POS’s advanced barcode scanning capabilities support both 1D and 2D codes. The system’s unique receipt barcode feature allows cashiers to instantly retrieve transaction details for returns or exchanges by scanning a barcode on the receipt, reducing errors and speeding up customer service.

KORONA POS’s extensive inventory management features make it a standout for retailers aiming to optimize their operations. The system offers automated reordering and ABC analysis to identify top-selling products, ensuring shelves are always stocked efficiently. Retailers can print shelf labels and price tags directly through the platform, with barcode integration that simplifies product categorization and pricing updates. KORONA POS maintains a centralized product catalog for multi-store operations, syncing inventory across locations and eCommerce platforms to eliminate manual data entry and reduce discrepancies. These tools empower businesses to make data-driven decisions and maintain seamless inventory control.

KORONA POS caters to retail verticals that benefit from barcode and inventory integration. Its features are particularly well-suited for businesses with large and diverse inventories, such as liquor stores, gift shops, CBD and smoke shops, bookstores, and convenience stores.

Beyond traditional retail, KORONA POS also serves the quick-service industry (like bakeries and coffee shops) and ticketing businesses (such as museums and amusement parks), where quick, accurate scanning is essential for managing sales and admissions. Sign up for a free demo with KORONA POS today and see how it can elevate your retail business