As we’ve talked about plenty on this blog, it’s absolutely critical that retailers keep an accurate physical inventory count at all times. It’s important to maintain proper levels of inventory to prevent your warehouse and storage from being overwhelmed by overstock but also to keep all of your shelves full and customers buying what they came for.

That, unfortunately, doesn’t mean it’s easy. Managerial errors, various sales channels, theft, inventory shrinkage, and more all make it remarkably hard to keep your physical stock optimized.

Luckily, there are ways to ensure your inventory stock is always in good shape. Getting the right inventory management system is the first step. But from there, you should think about cycle counting vs. physical count. Both give you more insight into your business operations, but for many SMBs, one will be more useful than the other.

Let’s define each of these and then help you determine which system is better for your business. And once you decide on the best plan of action, we can help your store implement the right tools to make it automated and convenient.

What Is Cycle Counting?

Cycle counting inventory is a form of perpetual inventory management. It counts your stock levels continuously over a predetermined period of time. The idea is that business owners and managers can keep their inventory optimized without having to conduct store-wide counts that interrupt your retail operations. Instead, only certain portions of your inventory are counted over certain time intervals.

What Is Physical Inventory?

A physical inventory count is one that is conducted of your entire product inventory at one time. The process of this count is much more time-consuming and often requires store closure for half of a day or full day (some retailers also complete physical counts overnight).

In fact, to complete an accurate physical inventory count, it requires temporary closure – without it, there would be inaccuracies for any shipment received or sale made while the count was being conducted.

Why Are Inventory Counting and Inventory Management So Important?

Accurate inventory counting is essential for running a smooth operation. You need to know exactly what’s on hand at any given time so you can plan your ordering, pricing, and promotions. Unfortunately, not enough retailers keep an accurate inventory.

It’s also critical for identifying any loss. If there are discrepancies, it’s important that they’re caught quickly and remedied. These can include inaccurate reporting, human error, internal theft, customer theft, vendor fraud, and return fraud, among others.

Like any problem, it’s critical to nip it in the bud before it gets any worse. Though cycle counts are usually more efficient, either type of inventory counting will provide you with more transparency and help optimize your inventory management.

What Are Some Stats on Retail Inventory Management?

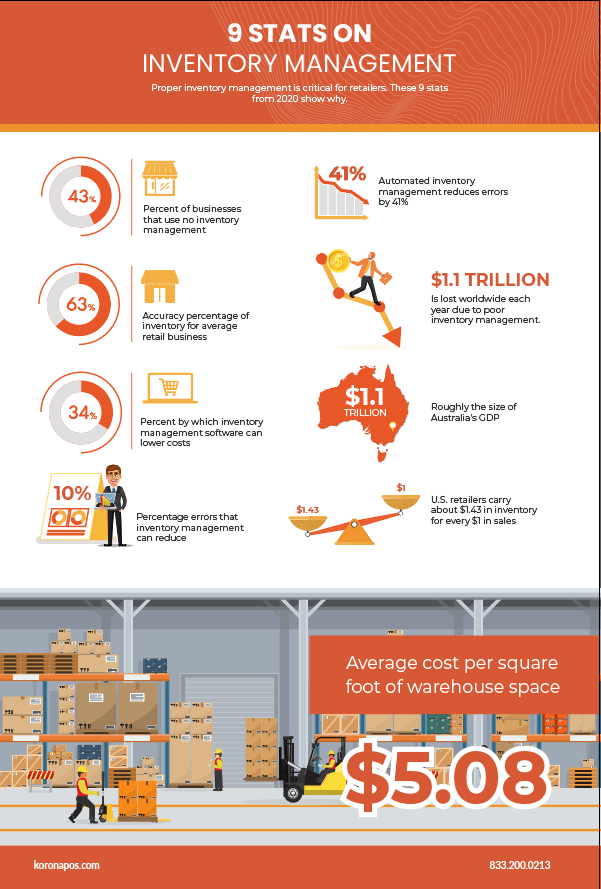

To illustrate just how ignored good inventory management is across the retail sector, here are a few stats that might help inspire you to make some changes:

- 43% of small businesses don’t use inventory tracking at all! Not even manually on a spreadsheet. This, of course, leads to forecasting problems.

- The average retail business only has an inventory accuracy of 63%. This will lead to stockouts and angry shoppers.

- 34% of eCommerce businesses have sent an order late because they were out of stock. There’s no way of competing with other online shops with late orders.

- $1.1 trillion are lost worldwide each year due to inaccurate inventory. This is about the same as the GDP of Australia.

- Improving inventory management can lower inventory costs by about 10%. Do the math and figure out how much your particular business will save every year.

- U.S. retailers have about $1.36 of inventory for every $1 in sales. This means that they’re overstocked.

Which Is Better? Cycle Count vs. Physical Inventory

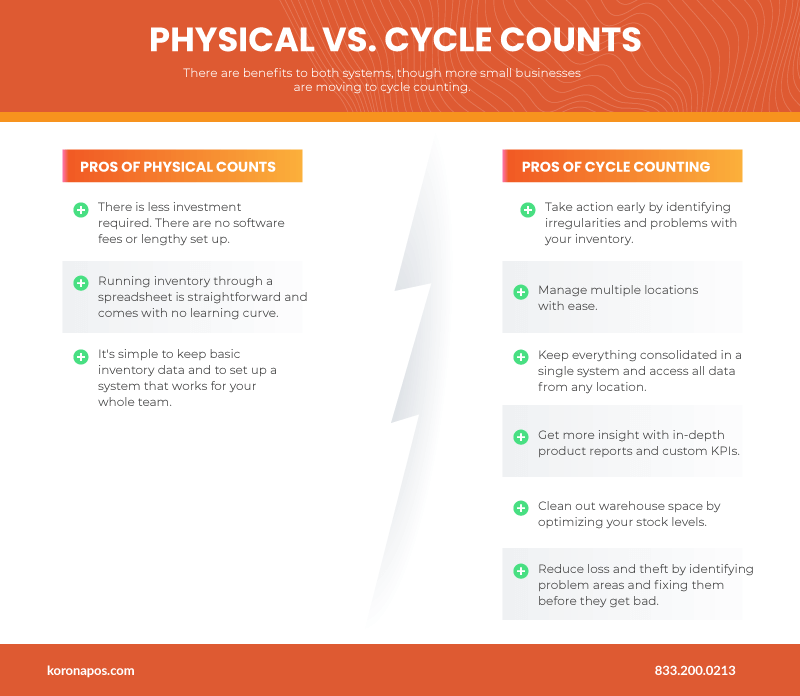

There are merits to each, but for most retail businesses, both small and enterprise-level, cycle counting is better.

For some single location, single terminal stores, physical inventory counting might be the better option. It won’t be as accurate or convenient, but there are some upsides:

Physical Count Benefits

Less investment – It’s easier to get up and running and requires no extra software fees.

Fast to set up – These don’t come with a learning curve for a new system. Instead, you need only enter the numbers in a spreadsheet and go from there.

Keep it simple – If you don’t have a lot of data to manage then just make it easy on yourself and make it a straightforward process.

But for most businesses, cycle counting will bring you a whole lot of benefit:

Cycle Count Benefits

Take action – Identify irregularities and problems quickly so you can make important changes right away.

Perfect for multi-location operations – Businesses that have multiple stores or are trying to scale will need cycle counting. More accuracy and automation is a requirement at that point.

Keep everything together – With a centralized inventory management system, your entire operation will be consolidated. Automate orders at each location, get custom reports from individual stores, and access it all remotely through the cloud.

Get more insight – Inventory software will come with custom reporting to give you actionable advice on how to better manage your products.

Clean up your warehouse – Cycle counting helps optimize your inventory and keep your warehouse from getting overwhelmed and cluttered.

Find areas of loss – Retail loss is a big problem. Find the areas of your operation that need improvement and cut back on your shrinkage.

How Do You Set Up Cycle Counting?

Start by determining the batches of items that you’ll count together. Remember, you’ll only be counting portions of your inventory each time.

Conduct an ABC analysis of your entire inventory. This can be run through your retail inventory management system. You’ll measure your products by profitability and divide them into 3 segments: the top 20%, middle 60%, and bottom 20%. Set unique cycle counts for each group. You’ll want your higher-performing groups to be counted more often.

Next, think about the seasonality of your products. If you sell items that are seasonable and in-season, count them more frequently. It’s particularly bad to run out of a popular item during a busy time of year for it. Take the time to customize your cycle counts based on your unique store.

If you prefer, you can also group your cycle counts by location on your retail store’s floor or warehouse space. Simply create a map of your store and determine how big each section will be. Just be sure that each section is counted at least several times per year.

No matter how you conduct your cycle counting, just make sure that you take a systematic approach to it. With the right retail software, setting it up and running the program will be a breeze, improving your ordering systems and keeping your shoppers happy.

Inventory management headache?

KORONA POS makes stock control easy. Automate tasks and get a clear picture of your entire inventory.

Get the Right Cycle Counting System with Your Inventory Management Software

KORONA POS offers some of the best inventory tracking software on the market. You’ll be able to automate operations, maintain seamless vendor relations, optimize order levels, set custom par levels, create store orders, get stock notifications, transfer stock, and a whole lot more.

To learn more click below to set up a trial account. Your dedicated product specialist will schedule a demo, too, so you can see the ins and outs of the system.