Key Takeaways:

- Keep an updated inventory list so you always know what’s in stock.

- Do regular stock checks and cleanups to catch errors and remove clutter.

- Create a stockroom SOP to make sure everyone follows the same process.

- Organize items logically and label shelves to save time and avoid confusion.

- Use inventory tools or software to track stock levels and set reorder alerts.

Running a small business involves many moving parts, and one area that often gets overlooked is stockroom management. An organized stockroom is essential for tracking inventory, streamlining operations, and improving your bottom line.

To help you get started, we laid out some key strategies for organizing your retail stockroom. Following these tips will not only help you save space and reduce clutter but also ensure you can keep an accurate count of all your items, from the moment you place a supplier order to the final sale. Read on to learn more.

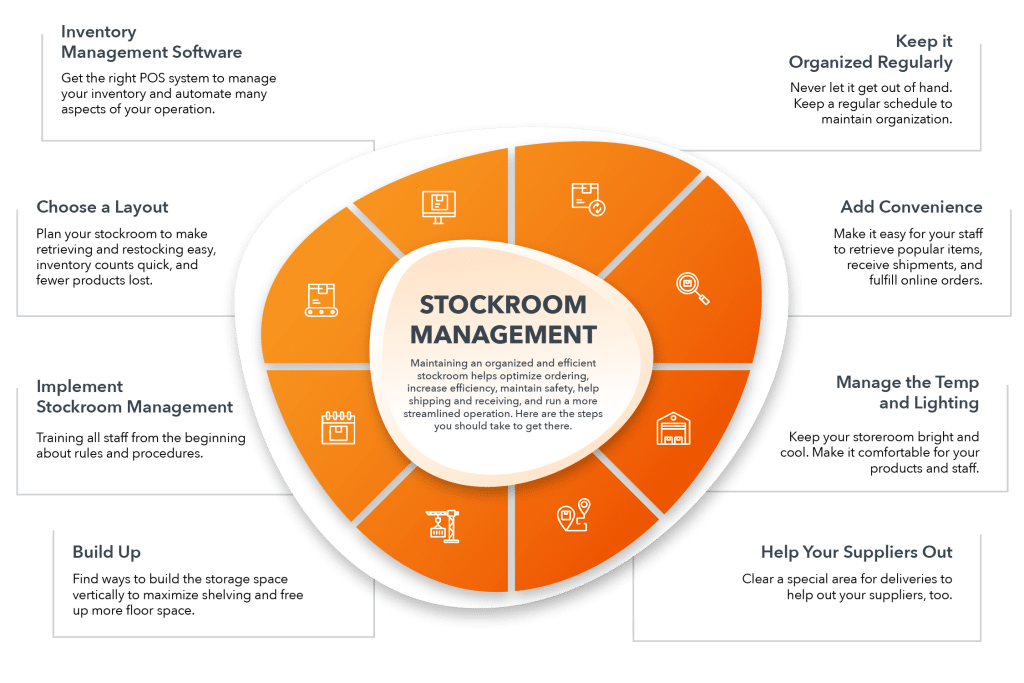

What Is Stockroom Management and Why It Matters?

Stockroom management, often used interchangeably with warehouse or inventory management, is the set of policies, processes, and systems a business uses to organize, track, and control its inventory.

It’s about ensuring a smooth flow of goods from receipt to sale or use.

It is vital for any business with physical stock, whether a small retail store, a large e-commerce company, or a manufacturing plant.

Key Components of Stockroom Management

- Inventory Tracking and Control: This involves knowing exactly what you have in stock, where it is located, and how much it’s worth. Modern systems use technology like barcode scanners and RFID tags for real-time tracking.

- Space Utilization: A core part of effective management is efficiently arranging your stockroom to make the most of the available space, including using vertical shelving and creating a logical layout.

- Process Management: It includes defining clear procedures for receiving new inventory, putting away items, picking and packing orders, and handling returns. Methods like “First-In, First-Out” (FIFO) are often used to ensure that older stock is sold first, especially for perishable goods.

- Demand Forecasting: Analyzing historical sales data and market trends to predict future demand helps you maintain optimal stock levels, avoiding overstocking and stockouts.

- Safety and Security: A well-managed stockroom has protocols to prevent theft and product damage. This also includes ensuring the space is safe for employees, with clear pathways and proper storage for heavy or hazardous items.

Why Stockroom Management Matters

Effective stockroom management is critical for business success for several reasons:

- Improved Efficiency and Productivity: An organized stockroom allows employees to find and retrieve products quickly, leading to faster order fulfillment and restocking. This reduces wasted time and effort, and boosts overall productivity.

- Cost Reduction: Accurate inventory counts and demand forecasts help businesses avoid holding excess stock, which ties up capital and increases storage costs. This also helps prevent losses from damaged, obsolete, or expired goods.

- Enhanced Customer Satisfaction: When you know what you have in stock and where to find it, you can fulfill customer orders accurately and on time. This minimizes the risk of backorders and wrong shipments, building customer trust and loyalty.

- Better Decision-Making: Real-time data from a well-managed stockroom provides valuable insights into what’s selling, what’s not, and which products are most profitable. This information empowers business owners to make informed purchasing, marketing, and sales decisions.

- Loss Prevention: A well-organized and secure stockroom helps deter theft and makes tracking and investigating any discrepancies easier, reducing “shrinkage” from lost or stolen goods.

1. Start with a Clear Inventory List

The best way to get your stockroom in shape is by starting with a solid, clear inventory list. Think of it as your master map. When you know exactly what you have on hand—down to every last item—you can stop guessing and start making smart decisions.

This initial, thorough count immediately shows you where the gaps are, like missing products or discrepancies between your records and the shelves. With that knowledge, you can set up a logical system, organizing everything so it’s easy to find and put away.

This not only makes your team’s life easier and your fulfillment faster, but it also gives you the hard data you need to avoid running out of popular items or getting stuck with a pile of stuff you can’t sell.

2. Get an Inventory Management System

We can start with the most important one. A reliable POS system with inventory management features is essential for most retail stores, particularly those with warehouses or stockrooms.

An inventory management system can improve your daily and long-term operations in many ways. It can automate ordering, optimize order levels, send notifications, communicate with vendors, transfer stock, and manage franchises.

Starting with a proper inventory system will help you better understand your products and, therefore, better organize your stock on hand on your shelves and in your stockroom.

Better organization means that you’ll more easily have the right amount of inventory on hand at any given time. This level of stock management is so important for keeping your shoppers happy by having everything they need, and your capital and stockroom space freed up by not ordering too much.

Inventory management a headache?

KORONA POS makes stock control easy. Automate tasks, generate custom reports, and learn how you can start improving your business.

3. Choose a Stockroom Layout

Aside from your inventory management software, your stockroom’s initial planning and layout is probably the most important item on the list.

A good stockroom layout will help your store succeed on a number of levels:

- Improved efficiency for restocking shelves

- More accurate and timely inventory counts

- Fewer lost products

- Reduced shrinkage from product damage

- Less stressed employees

- Better aesthetics for any guests who see the stockroom

Start by planning the basic rows and columns of the warehouse or stockroom. Map out where you’ll add shelving, desks, cabinets, drawers, and boxes. You’ll want to add storage space that will easily fit the size of the inventory you receive from suppliers.

Also, leave additional space initially. You want to leave some room for error if you forget something. Plus, your business may scale down the road, so you’ll need extra storage in your stockroom.

Some businesses should also consider adding mobile storage. This provides more flexibility for ebbs and flows in ordering throughout the year. Storage space is expensive, but it’s important to find solutions to ensure that you always have an adequate amount of space for your products.

4. Use Vertical and Modular Storage to Maximize Space

Just like retailers with limited space in their shopping areas, it’s essential to utilize vertical warehouse storage. Add shelves along all open walls and build well-spaced rows that can be expanded if additional space is needed in the future.

Still, you need to be sure that it’s safe and convenient. It’s important that your team members can access all products quickly and securely. And this should include people of all heights. Add stools and ladders if necessary. Check with your city to ensure they’re up to safety codes, and ask your staff if they’re all comfortable using the equipment.

5. Organize Products by Category and Accessibility

Even a small stockroom can get out-of-hand within days. And an out-of-hand stockroom means your business won’t run at peak capacity. Therefore, you must implement a system to keep it organized and clean regularly.

Depending on your product line, keep items sorted logically. Use different bins for various colors, sizes, brands, suppliers, etc. – whatever makes sense to you and your team.

💡PRO TIP

- Whatever the system, label all items clearly. Put rules in place, and delegate scheduled tasks to your staff. A well-organized stockroom keeps business running smoothly and also protects you from petty internal theft and retail fraud.

6. Implement Stockroom Management Rules and Staff Training

From the beginning, set up strict rules for your stockroom and train all new staff members accordingly. Like other aspects of keeping your business organized, a uniform policy helps keep workplace procedures simple and straightforward. Even if some rules seem over the top or unnecessary, it’s better to err on the cautious side.

When creating your stockroom policies, prioritize safety. It’s vital that your team has a safe space to work in at all times.

💡PRO TIP

- But also implement rules that promote cleanliness, organization, and efficiency. Most retailers opt to ban food and drink in the stockroom. Add some cameras in the back to ensure people behave appropriately and keep it a safe area of your store.

7. Make It Convenient to Reach Top Products

You want your team to be in and out of the stockroom as quickly as possible. Oftentimes, they’re back there to grab a product for a waiting customer or to restock shelves that are low in inventory. Either way, there is typically some urgency to the situation.

So make it easy for them. Plan your product layout so that similar items are grouped together in a logical way. Add the most commonly retrieved items conspicuously near the front of the room so your team members can keep moving quickly.

8. Ensure Proper Lighting, Climate, and Safety Measures

Some retailers will require far more sensitive climate control and lighting than others. People who run museums and open wine shops, for instance, need to be extra cautious about keeping their stockrooms at specific temperatures and lighting levels throughout the year.

Though other retail small businesses won’t need that attention to detail in this department, it’s still important to monitor these two items.

Keep the temperature manageable for your team. A hot stockroom or warehouse makes for a miserable working environment. If you operate in a humid region, add a dehumidifier in addition to your A/C—humidity can damage your packaging and products.

Lighting is also important for retail store equipment. You should focus on setting up a system that makes it easy to find items and maintain an appropriate level of safety. Bright lights make it easier to find items and watch one’s footing. Plus, there will inevitably be less lost in the back corners of your stockroom.

9. Make Shipping and Receiving Easy

Lastly, pay some attention to your shipping and receiving areas. Most brick-and-mortar retailers will have more products coming in than shipping out. But with more running an eCommerce side to their business in addition to their physical location, it’s important to plan for a designated space to ship out, too.

Make it convenient for any delivery people to unload and stack boxes. Not only do you want to make their lives easier, but you also want to ensure that your products aren’t being damaged in the arrival process.

10. Conduct Regular Stock Checks and Cleanups

Conducting regular stock checks and cleanups is a simple but powerful way to keep a stockroom running smoothly. It forces you to reconcile what’s actually on the shelves with what’s on paper while also keeping the space organized and usable.

By doing routine counts, you catch discrepancies early—whether it’s misplaced items, theft, or data entry errors—and that accuracy directly impacts purchasing decisions and order fulfillment. Cleanups, on the other hand, help remove expired, damaged, or obsolete stock, free up valuable storage space, and make it easier for staff to locate what they need without wasting time.

Together, these practices reduce clutter and waste and build a habit of discipline and accountability, which leads to a stockroom that’s more efficient, reliable, and cost-effective.

11. Create a Stockroom SOP

Creating a stockroom SOP (Standard Operating Procedure) sets clear rules for how everything should be handled—receiving, storing, counting, labeling, and even issuing stock. It eliminates the guesswork that often leads to mistakes.

When everyone follows the same process, items are always stored in the right place, records stay accurate, and new employees can get up to speed quickly without disrupting the workflow.

An SOP also makes it much easier to hold people accountable and troubleshoot problems, because you can quickly pinpoint where the process might be breaking down. In short, it turns what could be a chaotic, inconsistent mess into a reliable, efficient operation that runs smoothly no matter who is on duty.

Organize Your Retail Stockroom with KORONA POS

To learn more about how to manage your inventory as a whole, check out KORONA POS. The vast inventory management POS features are truly second to none. We’ll help your business make sense of your product line and get your retail store in order.

Better yet, you can try it all out free of charge. Create an account below and start uploading your product data. One of our product specialists will walk you through each feature so you can see how it will transform your business and help you scale.