Open-to-buy is a budget forecast for purchasing future products or items that a retailer develops for a specific time period. This plan aims to ensure better inventory management and make the best use of their purchases. An open-to-buy plan allows retail business owners to anticipate sales trends and avoid surplus or stock shortages.

Inventory management is the backbone of retail store operations. Poor inventory planning can have severe repercussions for business operations, such as delays in order shipment, product stock-outs, deadstock, and even shutting down the business. That’s why most retailers use a variety of inventory planning strategies, some of which include open-to-buy.

Also known as OTB, open-to-buy is a formula that allows you to determine the amount of money you need to purchase your inventory to meet your sales budget for a certain period. Open-to-buy is calculated at cost and allocated to different product categories following each category’s contribution to total sales. Read on to learn the open-to-buy formula, how to create an open-to-buy plan for your retail business, and much more.

Why is Open-To-Buy Critical For Retailers?

Open-to-buy is essential for retailers because inventory accounts for the most significant expense in retail. As a result, the investment in inventory must be productive, accurate, and timely. Not offering a product when your customers want it leads to lost sales and unsatisfied customers.

At the same time, having so much inventory that you can’t sell it fast enough results in markdowns that erode profit margins. Open-to-buy inventory planning will allow you to estimate the amount of stock you need to keep your business operations stable.

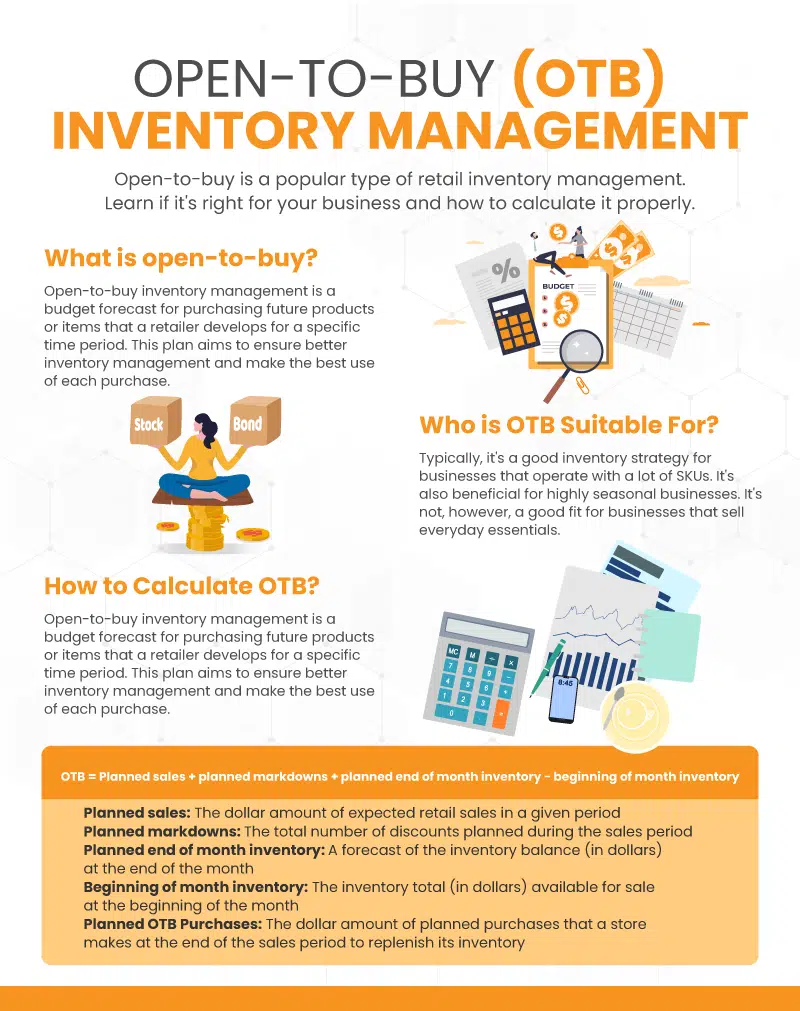

Who is OTB suitable for?

While open-to-buy planning is a replenishment tool used by all types of businesses, it is not suitable for all commodity categories. The industries that will benefit most from OTB are those where product specifications change regularly, but the classifications and subclassifications of those products remain the same.

This strategy is also beneficial for retailers who deal with many SKUs, such as apparel brands. It’s also helpful for highly seasonal businesses, where retailers need to buy the right amount of inventory early and gradually decrease the supply by a predefined endpoint.

Finally, open-to-buy planning is not designed for everyday items. Your most popular items, such as soft drinks or small accessories, are better suited to run on an automatic replenishment schedule. This is especially true for items that sell consistently throughout the year with no real peaks and dips in sales figures.

And, of course, since OTB planning is based on historical product sales data, it’s only a feasible strategy if the business is using an appropriate POS system.

The point of sale system is the backbone of retail store management. Therefore, you should make a fairly well-thought-out choice about the type of POS system you want based on your business needs. Not only does a POS system facilitate payment for in-store purchases, but it also provides you with valuable data about your customers and their preferences.

How To Calculate Your Own Open-To-Buy Budget?

Like any effective budgeting tool, the open-to-buy formula allows companies to calculate a reasonable forecast using their historical sales data while considering circumstances that may change those estimates. However, it should be noted that open-to-buy values are projections, which means they may not be perfectly accurate. That’s why it’s often advisable to check if your actual month-end inventory is within 5% of your forecast.

What Is the Open-to-Buy Formula?

OTB = planned sales + planned markdowns + planned end of month inventory – beginning of month inventory

Here are the meanings of the terms used in the OTB formula:

- Planned sales: The dollar amount of expected retail sales in a given period

- Planned markdowns: The total number of discounts planned during the sales period

- Planned end of month inventory: A forecast of the inventory balance (in dollars) at the end of the month

- Beginning of month inventory: The inventory total (in dollars) available for sale at the beginning of the month

- Planned OTB Purchases: The dollar amount of planned purchases that a store makes at the end of the sales period to replenish its inventory.

For example, a women’s shoe retailer is assumed to have an inventory level of $100,000 on July 1 and a projected month-end inventory of $110,000 for July 31. The expected sales for the store are $20,000 with $750 in expected markdowns. As a result, the retailer has $30,750 in retail OTB.

Open-to-buy = ($110,000+$20,000+$750) – $100,000 = $30,750

Note: Multiply this number by the initial markup (IMU) to get the OTB at cost. If our markup is 30%, our OTB at cost is $9,225. Before implementing your OTB plan, make sure each number is realistic and fits your way of doing business. Remember that many of the numbers in your inventory plan are just guidelines; they don’t have to be perfect. For example, if your actual ending inventory is within 5% of your plan, then your inventory management is on the right track.

How To Create an Open-To-Buy Plan?

The success of OTB planning depends on the accuracy of projections for each aspect of the formula. Realistic forecasts are essential to achieving actionable results and getting the most out of the OTB concept.

- Step One – Develop a sales plan. It is advisable for small retailers to create monthly sales plans rather than weekly ones. However, highly seasonal businesses can benefit from weekly sales plans.

- Step Two – Set up an inventory plan. Ask yourself how much inventory you need to have to support your projected sales and maintain adequate stock to handle peak sales.

- Step Three – Once you have established the sales and inventory plans, you can create planned markdowns and inventory adjustments.

- Step Four – Create an inventory receipt plan. For any given period, you can insert the remaining numbers into the open-to-buy formula to determine how much inventory you need. Obviously, you should also take the time to compare your projected numbers for a period with your actual numbers. If it’s inaccurate, it’s certainly not worth your efforts to use this inventory management strategy.

Open-To-Buy vs. Inventory Management Software

Finally, you’ll need to use it in conjunction with your retail software. Inventory management is a remarkably complicated endeavor, and you may run into problems if you don’t have the whole picture. Some metrics are missing from the open-to-buy formula, such as order cycle time, inventory carrying costs, and inventory shrinkage.

KORONA POS has exceeded my expectations in every way. It’s a powerful, adaptable solution that has transformed our operations for the better.

-James B.

That’s why it’s best to opt for automated inventory management software. The software saves you from manual calculations, which can be subject to errors, or from using spreadsheets and gives you more accurate estimates of your inventory. KORONA POS inventory management software provides users with automated reordering, stock transfers, store order cycles, and even notifications if they’re running out of some products.

Click on the button below to learn more about how KORONA POS can help you better manage your items.

FAQs: Open-To-Buy Retail

Retailers adopt the open-to-buy approach because it is an inventory management strategy that allows for optimal stock levels, more flexible inventory, and the identification of product trends that are likely to be appreciated by consumers.

Retailers adopt the open-to-buy approach because it is an inventory management strategy that allows for optimal stock levels, more flexible inventory, and the identification of product trends that are likely to be appreciated by consumers.

The open-to-buy is calculated as follows: OTB = planned sales + planned markdowns + planned end of month inventory – beginning of month inventory.

You can create an OTB planning in four steps. The first step is to develop a sales plan. Next, establish an inventory plan and create planned markdowns and inventory adjustments. Finally, create an inventory receiving plan.